PLC hanging roller mill

PLCbased Load Management in Steel Rolling Mills

2010年6月1日 The case study of a typical steel rolling mill, with the proposed model, shows that savings of about 521% in electricity costs are possible with PLC controls stepping motor running and welding torch starting arc and ending arc Communication between the touch screen and PLC improves the efficiency of the system and The Design of Rolling Mills’ Automatic Control System Based on PLCIn order to realize the automatic control of 1150 blooming mill, hydraulic screwdown devices and the automatic control system of hydraulic screwdown position are used, and Siemens PLC is The Design of Rolling Mills’ Automatic Control System Based on PLCCompactRIO Connects Easily to Existing PLC Architecture Each rolling mill contains three networked CompactRIO systems All three CompactRIO systems are intelligent nodes that I2S Uses CompactRIO to Optimize PLC Automation in Steel Rolling

Looper angle and looper tension control between roll stands in

Abstract— In this article, the development of parameterization of the controller for looper control angle and tension in hot strip finishing mills is traced based on Inverse Linear Quadratic (ILQ) This design is based on S7300 PLC monitoring system of rolling mill, and it uses the PLC ladder diagram and configuration software communication to realize effective monitoring of rolling The Application of PLC in Automatic Rolling Mill Monitoring SystemThe case study of a typical steel rolling mill, with the proposed model, shows that savings of about 521% in electricity costs are possible with optimal load scheduling under TOU tariff AfterPLCbased Load Management in Steel Rolling Mills ResearchGate2010年6月15日 The case study of a typical steel rolling mill, with the proposed model, shows that savings of about 521% in electricity costs are possible with optimal load scheduling under PLCbased Load Management in Steel Rolling Mills

Programmable controllers for special control applications in rolling

1995年1月7日 The paper deals with automation of a single stand aluminium cold rolling mill using programmable controllers and PC's It highlights the various special functions realized 2022年10月27日 The looper control of hot strip finishing mill is one of the most critical control items in hot strip rolling mill process It is a highly complex nonlinear system, with strong states Looper and tension control in hot strip finishing mills based on ZENITH grinding mills are able to meet 080mesh, 80425mesh, 4253000mesh mineral grinding demands And ZENITH grinding mills are widly used in paper making, GCC, coating, fertilizer, Hanging Roller Mill; Ultrafine Mill; Vertical Mineral Equipments Zenith Crusher1254 Roller Mill with folding Auger Video 1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper 1254 Roller Mill with 18' Belt Discharge Flyer Click to request More Info Built with the operator in mind, our Roller Mills are Roller Mill

.jpg)

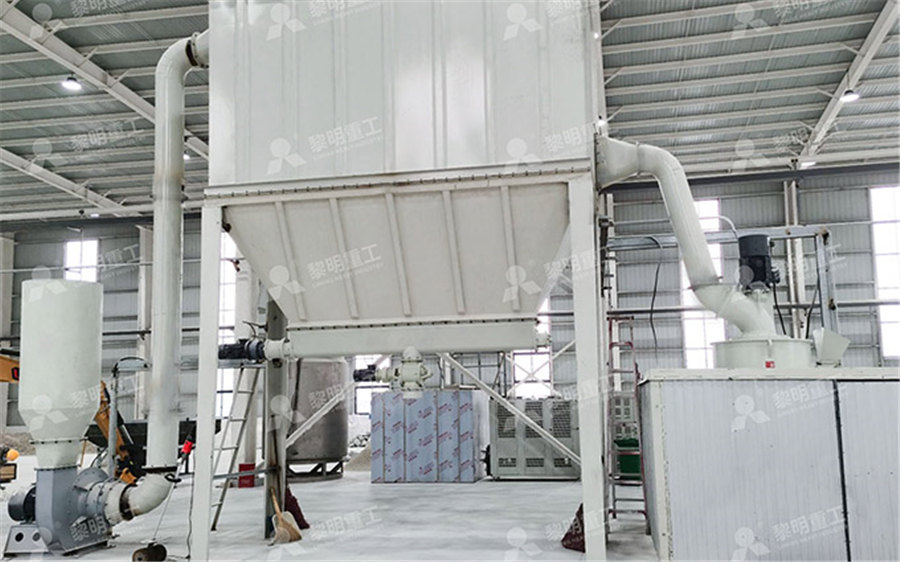

MB5X Pendulous Hanging Grinding Mill

MB5X Pendulous Hanging Grinding Mill MB5X pendulous hanging grinding mill represents the most advanced grinding processing technology at present, and its application of patent technology of brandnew structural design makes the equipment's operation and maintenance cost much lower, environmental protection performance more excellent and discharging 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, the feeding section, the return windbox, the discharge section, etc There are three to five rollers hanging on the rack, each of which has a sloped blade in front (Fig 4)Roller Mill SpringerLinkHighpressure hanging roller mill☎ WA:+861⃣3⃣8⃣1⃣6⃣7⃣1⃣1⃣1⃣2⃣3⃣📧:sales@dingbocrusher💻Click web for price:https://www Highpressure hanging roller mill YouTubeThe LAM roller mill was manufactured from the late 80’s to early 2000’s by OCRIM spa in Cremona, Italy, in various versions variable speed electric gear motors, infraredbased feed sensors, and a PLC panel to replace the old control system CETEC produces kits for all the different versions of the LAM, including the pneumatic LAM ROLLER MILL CONVERSION CETEC Cereal Technologies

Φ150~220/Φ600x800钢厂四辊冷轧机 佛山市格林普斯

Work roll or backup roll drive: Pressing down: Hydraulic AGC: Main motor: 361~500KW: 361~500KW: Coiling: Hydraulic pyramid type: Hydraulic pyramid type: Electric control: PLC Programming of Euro 590 Full Digital Control System: HP hydraulic: For bending roll system: Other: Hydraulic hanging roll balance, hydraulic roll unloadingCracking your grains with a roller mill will save producers money in the long run, especially as the price of feed/corn rises There are different kinds of roller mills including trailer roller mills, blower roller mills, stationary roller mills, and hanging roller mills Roller Mills from Post EquipmentRoller Mills for sale Post EquipmentA Two Roll Mill, commonly employed in the plastics and rubber industries, is a machinery used for compounding, processing, and shaping highmolecularweight materials like rubber and plastics Two roll rubber mill typically consists of two parallel rotating cylinders that facilitate mixing, processing, and contour adjustments of the materials through a combination of compression Laboratory Two Roll Mill Automatic Rollover PLC Program A Two Roll Mill, commonly employed in the plastics and rubber industries, is a machinery used for compounding, processing, and shaping highmolecularweight materials like rubber and plastics Two roll rubber mill typically consists of two parallel rotating cylinders that facilitate mixing, processing, and contour adjustments of the materials through a combination of compression Laboratory Two Roll Mill Automatic Rollover PLC Program

360 Rubber Calendering Machine with PLC Control

Main Application : This machine is used for calendering of rubber or plastics, fabric fraction and coating, sheeting and composite of rubber or plastics 11Basic introduction of 360 rubber calendering machine with PLC control two 38 Energy Engineering Vol 107, No 4 2010 PLCbased Load Management in Steel Rolling Mills Ashok S, Senior Member IEEE ABSTRACT This article presents a physicallybased load model and formulaPLCbased Load Management in Steel Rolling Mills ResearchGatefilms on the mill, avoiding that the very thin wrap around layer on the front roll will creep under the side platen The Teflon side guides are supplied tiltable All Two Roll Mills are supplied with a special Material Scraper Knife with a thick bronze blade Laboratory TwoRoll Mills ReotermTRH type three roll mill is a hydraulic three roll mill with a PLC system Through a simple graphical touch screen, the operator can easily get started and control the machine more accurately and stably Skip to content Wet Grinding Equipment Three TRH three roll mill|Hydraulic type with PLC Franli Machine

.jpg)

PLC Roll Mill MadeinChina

China PLC Roll Mill wholesale Select 2024 high quality PLC Roll Mill products in best price from certified Chinese PLC manufacturers, Best Plc suppliers, wholesalers and factory on MadeinChinaThe threeroll mill is a crucial piece of equipment used for the grinding and dispersing of various materials such as paints, inks, pigments, plastics, The laboratory three roll mill is equipped with the most advanced PLC functions to continuously improve the operability of the most primitive production equipment 09 NovemberThree roll mill: A Machine Used To Mix, Fefine, or Disperse MaterialsThis work is supported by publication, the hot strip mill looper system in IEEE Transactions on Industry Applications e LooperTension almost disturbance decoupling control for hot strip finishing mill based on feedback linearization in IEEE Transactions on industrial electronics g Winders to roll the material in hot strip coilsLooper angle and looper tension control between roll stands in Lab three Roll mill contains a PLC system on top on which you can set any formula to add the date or gap of the rollers that make your work easier than any other machine Lab three Roll mill is ideal in those companies that are deal in grinding and mixing tasks regularlyLab three roll mill |Compatible with PLC system

.jpg)

Dunelm The UK's Leading Home Furnishings Retailer

Welcome to Dunelm, the UK's leading home furnishing retailer Shop for bedding, curtains, furniture, beds and mattresses today at DunelmView more Customized Roller Plc Lab Two Roll Mill With Emergency Protection Device , please visit https://ecer/corp/uuu4w02rubbertestingmachine/guucCustomized Roller Plc Lab Two Roll Mill With EmergencyHigh quality 5 Roller Carbon Steel Cold Rolling Mill Machine PLC For Making Seamless Tube from China, China's leading Cold Rolling Mill LD120 fiveroller cold rolling mill is applicable to state rolling,such as carbon steel,alloy Cold Rolling Mill, 5 Roller Carbon Steel Cold Rolling Specification of Cold Rolling Mill roller Type 4roller , 6roller, 8roller, 12roller, 20roller cold rolling mill Stand Type singlestand reversible cold rolling mill; tandem cold rolling mill( from 3 stands to 6 stands) Size of finished products Siemens PLC Controlled Cold Rolling Mill

Laboratory Two Roll Mill Automatic Rollover PLC Program

A Two Roll Mill, commonly employed in the plastics and rubber industries, is a machinery used for compounding, processing, and shaping highmolecularweight materials like rubber and plastics Two roll rubber mill typically consists of two parallel rotating cylinders that facilitate mixing, processing, and contour adjustments of the materials through a combination of compression 2022年11月9日 ② The laboratory three roll mill is equipped with a PLC touch control system Through a simple touch, the distance between each roller can be adjusted to ensure parallelism between the rollers Equipped with an elastically tensioned scraper socket to ensure constant pressure on the scraper, Laboratory Three Roll Mill|PLC Control System ExperimentalA triple roller mill is mainly used for various highgrade pastes, such as glues, paints, inks, plastics, pigments, cosmetics, electronic pastes, solar silver pastes, aluminum pastes, glass solder pastes, etc And it is especially suitable for products with high viscosity and high particle size requirements And triple roller mill has many kinds of rollers, such as chilled gold cast iron Triple Roller Mill|Grinding Of High Viscosity MaterialsHanging grinding mill Hanging Roller Mill, also known as vertical mill, is a common cement grinding equipment Compared with traditional horizontal mills, suspended mills use vertically arranged grinding discs and drums that operate by hanging on a shaft This design makes the Hanging Roller Mill more adaptable and productive in cement productionHanging Roller Mill in cement production

Roller Mill

1254 Roller Mill with folding Auger Video 1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper 1254 Roller Mill with 18' Belt Discharge Flyer Click to request More Info Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintainThe “free hanging” heavy duty chain drive system we use on all our tworoll mills enables movement of the front roll for NipGap adjustments without any negative e˛ect on the drives which you otherwise would encounter on traditional tworoll Laboratory TwoRoll MillsRest of the 3 system is electronic system and can be controlled easily from the panel In the full automatic PLC roller mill automation roller mill roll gap can be adjusted from sides synchronously and this adjustment can be controlled remotely Type: FORTIMUS ROLLER MILL Selis Real InnovationPLC Controlled Hydraulic Three Roller Mill, Find Details and Price about 3 Roller Mill Triple Roller Grinder from PLC Controlled Hydraulic Three Roller Mill Qingdao Shindah Machinery Co, Ltd Print This PagePLC Controlled Hydraulic Three Roller Mill China 3 Roller Mill

Mineral Equipments Zenith Crusher

ZENITH grinding mills are able to meet 080mesh, 80425mesh, 4253000mesh mineral grinding demands And ZENITH grinding mills are widly used in paper making, GCC, coating, fertilizer, Hanging Roller Mill; Ultrafine Mill; Vertical 1254 Roller Mill with folding Auger Video 1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper 1254 Roller Mill with 18' Belt Discharge Flyer Click to request More Info Built with the operator in mind, our Roller Mills are Roller MillMB5X Pendulous Hanging Grinding Mill MB5X pendulous hanging grinding mill represents the most advanced grinding processing technology at present, and its application of patent technology of brandnew structural design makes the equipment's operation and maintenance cost much lower, environmental protection performance more excellent and discharging MB5X Pendulous Hanging Grinding Mill2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, the feeding section, the return windbox, the discharge section, etc There are three to five rollers hanging on the rack, each of which has a sloped blade in front (Fig 4)Roller Mill SpringerLink

.jpg)

Highpressure hanging roller mill YouTube

Highpressure hanging roller mill☎ WA:+861⃣3⃣8⃣1⃣6⃣7⃣1⃣1⃣1⃣2⃣3⃣📧:sales@dingbocrusher💻Click web for price:https://www The LAM roller mill was manufactured from the late 80’s to early 2000’s by OCRIM spa in Cremona, Italy, in various versions variable speed electric gear motors, infraredbased feed sensors, and a PLC panel to replace the old control system CETEC produces kits for all the different versions of the LAM, including the pneumatic LAM ROLLER MILL CONVERSION CETEC Cereal TechnologiesWork roll or backup roll drive: Pressing down: Hydraulic AGC: Main motor: 361~500KW: 361~500KW: Coiling: Hydraulic pyramid type: Hydraulic pyramid type: Electric control: PLC Programming of Euro 590 Full Digital Control System: HP hydraulic: For bending roll system: Other: Hydraulic hanging roll balance, hydraulic roll unloadingΦ150~220/Φ600x800钢厂四辊冷轧机 佛山市格林普斯 Cracking your grains with a roller mill will save producers money in the long run, especially as the price of feed/corn rises There are different kinds of roller mills including trailer roller mills, blower roller mills, stationary roller mills, and hanging roller mills Roller Mills from Post EquipmentRoller Mills for sale Post Equipment

.jpg)

Laboratory Two Roll Mill Automatic Rollover PLC Program

A Two Roll Mill, commonly employed in the plastics and rubber industries, is a machinery used for compounding, processing, and shaping highmolecularweight materials like rubber and plastics Two roll rubber mill typically consists of two parallel rotating cylinders that facilitate mixing, processing, and contour adjustments of the materials through a combination of compression A Two Roll Mill, commonly employed in the plastics and rubber industries, is a machinery used for compounding, processing, and shaping highmolecularweight materials like rubber and plastics Two roll rubber mill typically consists of two parallel rotating cylinders that facilitate mixing, processing, and contour adjustments of the materials through a combination of compression Laboratory Two Roll Mill Automatic Rollover PLC Program