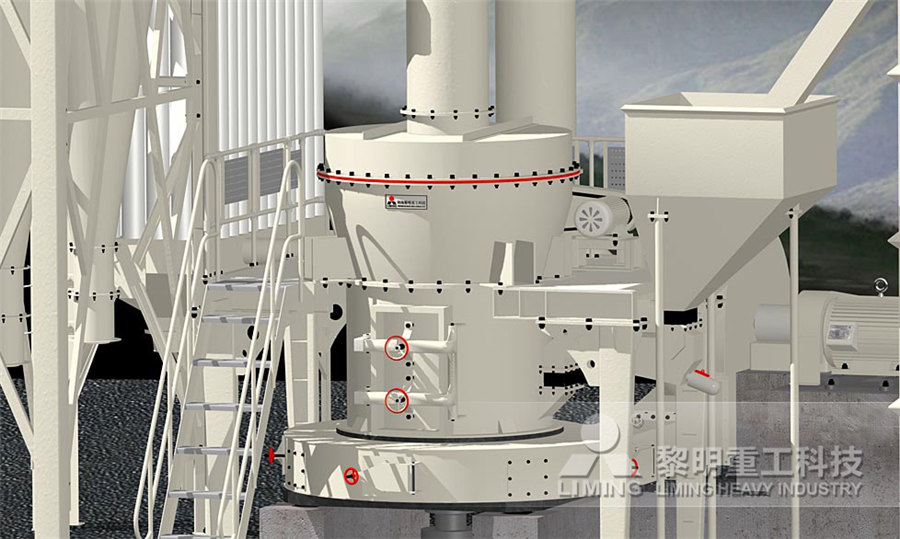

Layout of microcrystalline glass production line

CNU Microcrystalline glass production line Google

The utility model relates to a microcrystalline glass production facility technical field specifically is a microcrystalline glass production line, two equidistant even rotationThis glass ceramic production line through setting up aircooler, tuber pipe, control panel, violently managing and temperature sensor cooperation, realizes carrying out quick refrigeratedMicrocrystalline glass production line Google PatentsThe production line of the ultralowexpansion microcrystalline glass mainly comprises a melting furnace, a forming machine, an annealing furnace, a crystallizing furnace, a conveyingCNA Production line of ultralowexpansion Given the size and the complexity of the problem, we propose a twophase heuristic approach where the layout and sequencing aspects of the problem are addressed independently On a Optimization of Automated Float Glass Lines H Milton Stewart

.jpg)

FROM FEEDER UP TO ANNEALING LEHR – PRODUCTION LINES

technologies as well as reliable production lines and components delivering improved resource efficiency, reduced energy consumption, higher output and datadriven process optimization In this work a numerical model, based on the finite element method, for all processes of glass forming of glass containers is presented1: Production line of glass containers [12] ResearchGateIn this paper, a design of optimal facility layout, for already existing factory, using a Schmigalla method combined with software tool visTABLE for layout modelling and optimization, isFlowchart for the glass manufacturing process line2017年10月25日 This paper presents a digital twinbased approach for rapid individualized designing of the hollow glass production line The digital twin merges physicsbased system A Digital TwinBased Approach for Designing and MultiObjective

.jpg)

A Digital TwinBased Approach for Designing and MultiObjective

This paper presents a digital twinbased approach for rapid individualized designing of the hollow glass production line The digital twin merges physicsbased system modeling and distributed In this chapter, the basics of industrial glass production are described, from the selection of the raw materials to the delivery of a homogeneous glass melt to the forming processIndustrial Glass Processing and Fabrication SpringerLink2024年8月19日 A production layout guide is a document that helps businesses map their factories in a way that’s understandable to all teams and workers Product layout — Arrange machines and workstations in a line according to Production Layout Guide: How to Design a Factory 18 elements constitute this automatic line for the production of laminated glass To see more details of each section, you can download the dedicated catalog on the DOWNLOAD page HIGH PRECISION PRESS High precision press for laminated glass, standard and irregular shapes "INLINE" LAYOUT Aligned plant for glass sheet of big sizes x Triulzi AUTOMATIC PRODUCTION LINE FOR LAMINATED GLASS

CNB Microcrystalline glass crystallization production line

The invention relates to the field of microcrystalline glass production equipment, in particular to a microcrystalline glass crystallization production line, which comprises a crystallization furnace, wherein a feeding device is arranged at the inlet end of the crystallization furnace, and the feeding device comprises a support, an input mechanism, a rotary conveying mechanism and a lifting 2023年4月29日 Product layout: In the product or assembly line layout people, equipment, or departments are arranged along an assembly line for production of high volume goods Assembly line means a series of workstations at which already made parts are assembled Such layouts are used for products requiring a continuous or repetitive production processThe four types of production facility layout CH BlogWe can provide with the complete production line needed to manufacture cookware glass lids There are various stages (from cutting glass to making the outer steel ring) in order to manufacture cookware glass lid We take up turnkey projects for this domain with complete setup details, manufacturing details and project estimatesCookware Glass Lid Production Line Project Details Layout Glass 2021年6月18日 Green manufacturing is a growing trend, and an effective layout design method for production lines can reduce resource wastage in processing This study focuses on existing problems such as low equipment utilization, long standby time, and low logistics efficiency in a mixedflow parallel production line To reduce the energy consumption, a novel method Layout design of a mixedflow production line based on

.jpg)

China Microcrystalline Glass Production Line Manufacturers

With highquality Glass Forming Machine, Glass Cola Bottle Making Machinery, Furnace Air Exchanger, good reputation and highquality service, our company enjoys a good reputation at home and abroadWe continuously enhance the competitiveness of Microcrystalline Glass Production Line in the domestic and international market, enhance customer satisfaction and 31 Production of microcrystalline sintered corundum grains Microcrystalline sintered corundum grains are produced in a chemical process in which microcrystalline alumina oxide, acquired using the expensive solgel technology, is sintered [8, 1012, 20, 2528] Figure 5 State of the art in production, properties and applications of the b) World production of conventional abrasive grains in 2011 Silicon carbide (SiC) 1 010 000 t Fused alumina (Al2O3) 1 190 000 t World production of superhard abrasive grains in 2008 cBN 640 t Microcrystalline cBN 108 t Microcrystalline synthetic diamond 976 t Natural diamond 300 t Synthetic diamond on saw blades 7820 t Synthetic diamond for grinding processes 1312 t State of the art in production, properties and applications of the bound by the sampling rate of the linear camera Advances in glass production processes require systems with faster production lines (from 5 m/s up to 10 m/s and over) and high accuracy in defects detection Linear scan cameras with a higher sampling rate must be used to ensure that detection accuracy is kept constant or increased when the Fast Blob and Air Line Defects Detection for High Speed Glass

.jpg)

TYPICAL PHYSICAL ATTRIBUTES OF MICROCRYSTALLINE

Tomar et al, IJPSR, 2018; Vol 9(4): 15451554 EISSN: 09758232; PISSN: 23205148 International Journal of Pharmaceutical Sciences and Research 1545A glassceramic and production line technology, which is applied in the field of manufacturing laser navigation equipment and lithiumaluminumsilicon ultralow expansion glassceramics, and can solve the problems of noncontinuous production of glassceramic industrial production linesProduction line of ultralowexpansion microcrystalline glass2021年10月1日 Producing glassceramics is largely determined by the preparation of parent glass whose crystallization process is of great importance (Chen and Zhang, 2011; Karamanov et al, 2003)This process is closely related to the heat treatment schedule, including 4 critical parameters, nucleation temperature (T G), nucleation time (t n), crystallization temperature (T Production of glassceramics from metallurgical slagsSemiautomatic laminated glass production line mainly includes a prepressing production line and an autoclave system The prepressing production line is mainly composed of a horizontal washing machine, a PVB film layout machine, a combined positioning conveyor, a walking suction cup hanger, and a convection prepressing machineSemiAutomatic Laminated Glass Production Line BolayMac

.jpg)

Float Glass Production Lines CMS Glass Machinery

tandem press insulated glass production line for over sized glass units more details vertical glass washing machine more details horizontal glass washing machine more details glass sealing extruders and robots automatic glass sealing robot more details glass sealing extruder more details butyl extruder – 7kgThe hot end corresponds to the part of the furnace where melting, forming and annealing processes occur The cold end, downstream of the forming and annealing processes, is where postprocessing such as coating, cutting and inspection take place An example of an industrial float glass production line is shown in Fig 348Industrial Glass Processing and Fabrication SpringerLinkDevelopment of OEE Errorproof (OEEEP) Model for Production Process Improvement 60 NOMENCLATURE G Quality products delivered per unit time (year) p G Total quantity produced per unit time (year Flowchart for the glass manufacturing process lineMicrocrystalline Glass Production Line The microcrystalline glass production line is mainly composed of the following parts: glassware forming machine, horizontal type mouth dryer with ejection mechanism to facilitate automatic pinching out, drying mouth combustion system, pincer cup manipulator, conveyor systemChina Microcrystalline Glass Production Line Manufacturers,

.jpg)

Characterization of the thermal properties of microcrystalline

2002年2月1日 The purpose of this study was to characterize the thermal properties of microcrystalline cellulose (MCC) and to investigate the influence of water on these propertiesPlenty of manufacturers struggle with issues relating to production line layout design, and one of the biggest reasons is because their products are frequently changing Production Line Considerations What is Factory Layout A "layout" refers to a plan or draft of a detailed visualisation for later executionMain Consideration for Production Line Layout Design Lenoch 2022年8月29日 The production line has simple process, high production efficiency, large output and low operating cost The finished sand and gravel have uniform particle size and good particle shape, which is very in line with the Dolomite crushing and sand making production line2017年10月25日 A Digital TwinBased Approach for Designing and MultiObjective Optimization of Hollow Glass Production Linepdf Available via license: CC BYNCND 40 Content may be subject to copyrightA Digital TwinBased Approach for Designing and

EASTGLAZ Glass Processing Machines, Glass

Insulating glass processing machine manufacture the highest performing insulating glass units such double glass, triple glass and structural glass façade units Automatic Insulating glass production line has 7 sections: Transfer Download scientific diagram Case study: process flow of a glass manufacturing factory from publication: Overall throughput effectiveness (OTE) metric for factorylevel performance monitoring Case study: process flow of a glass manufacturing factory2024年10月5日 This study aims to prepare and characterize microscale cellulose particles from waste for potential use as a reinforcement material in composites Thus, cellulose particles were obtained using a twostage chemical–mechanical acid hydrolysis method involving, a nitric acid (HNO3)acetic acid (HAc) solution followed by mechanical grinding Morphological properties Optimized production and comparative analysis of microcrystalline The structural features of an automatic glass conveying production line mainly include the following aspects: High Automation: The production line integrates equipment such as conveyor belts, robotic arms, glass edging machines, cutting machines, and washing machines, capable of automatically completing a series of processing steps for glass, including cutting, edging, and Glass conveying production line数字化智能生产线

.jpg)

Sustainable Production of Microcrystalline Cellulose Through

2024年3月25日 Conventional microcrystalline cellulose (MCC) production via aqueous mineral acid hydrolysis is energy and waterintensive, generating high wastewater volumes An alternative green chemistry approach employs concentrated gaseous acids to enhance yield and conserve resources This work aimed to develop an efficient, sustainable gasphase 2017年12月15日 In contrast, the simplicity of MFC production using a mechanical treatment only as well as a product yield near 100% ensures low production costs and easy process implementation The final material is obtained without any chemical or biochemical pretreatments directly from commercial MCC, which makes it potentially suitable in many of the sensitive The chemicalfree production of nanocelluloses from microcrystalline The invention discloses an automatic production line for spraying flexible microcrystalline glass on the inner wall of a metal straight pipe, which has the advantages that a powder spraying mechanism, a pipe fitting positioning mechanism and a pipe fitting heating mechanism are cooperatively matched, a gun barrel with automatic feeding and realtime water cooling CNA Automatic production line for spraying flexible 3D Microcrystalline Glass Ceramic Tile Equipment Production Line, Home Product Directory Manufacturing Processing Machinery Ceramic Machine 3D Microcrystalline Glass Ceramic Tile Equipment Production Line FOB Price: US$ 12,20000 / Piece: Min Order: 3 Pieces Min Order FOB Price; 3 Pieces: US$12,20000: Port: Wuhan, China 3D Microcrystalline Glass Ceramic Tile Equipment Production Line

Production Layout Guide: How to Design a Factory

2024年8月19日 A production layout guide is a document that helps businesses map their factories in a way that’s understandable to all teams and workers Product layout — Arrange machines and workstations in a line according to 18 elements constitute this automatic line for the production of laminated glass To see more details of each section, you can download the dedicated catalog on the DOWNLOAD page HIGH PRECISION PRESS High precision press for laminated glass, standard and irregular shapes "INLINE" LAYOUT Aligned plant for glass sheet of big sizes x Triulzi AUTOMATIC PRODUCTION LINE FOR LAMINATED GLASSThe invention relates to the field of microcrystalline glass production equipment, in particular to a microcrystalline glass crystallization production line, which comprises a crystallization furnace, wherein a feeding device is arranged at the inlet end of the crystallization furnace, and the feeding device comprises a support, an input mechanism, a rotary conveying mechanism and a lifting CNB Microcrystalline glass crystallization production line 2023年4月29日 Product layout: In the product or assembly line layout people, equipment, or departments are arranged along an assembly line for production of high volume goods Assembly line means a series of workstations at which already made parts are assembled Such layouts are used for products requiring a continuous or repetitive production processThe four types of production facility layout CH Blog

Cookware Glass Lid Production Line Project Details Layout Glass

We can provide with the complete production line needed to manufacture cookware glass lids There are various stages (from cutting glass to making the outer steel ring) in order to manufacture cookware glass lid We take up turnkey projects for this domain with complete setup details, manufacturing details and project estimates2021年6月18日 Green manufacturing is a growing trend, and an effective layout design method for production lines can reduce resource wastage in processing This study focuses on existing problems such as low equipment utilization, long standby time, and low logistics efficiency in a mixedflow parallel production line To reduce the energy consumption, a novel method Layout design of a mixedflow production line based on With highquality Glass Forming Machine, Glass Cola Bottle Making Machinery, Furnace Air Exchanger, good reputation and highquality service, our company enjoys a good reputation at home and abroadWe continuously enhance the competitiveness of Microcrystalline Glass Production Line in the domestic and international market, enhance customer satisfaction and China Microcrystalline Glass Production Line Manufacturers 31 Production of microcrystalline sintered corundum grains Microcrystalline sintered corundum grains are produced in a chemical process in which microcrystalline alumina oxide, acquired using the expensive solgel technology, is sintered [8, 1012, 20, 2528] Figure 5 State of the art in production, properties and applications of the

State of the art in production, properties and applications of the

b) World production of conventional abrasive grains in 2011 Silicon carbide (SiC) 1 010 000 t Fused alumina (Al2O3) 1 190 000 t World production of superhard abrasive grains in 2008 cBN 640 t Microcrystalline cBN 108 t Microcrystalline synthetic diamond 976 t Natural diamond 300 t Synthetic diamond on saw blades 7820 t Synthetic diamond for grinding processes 1312 t bound by the sampling rate of the linear camera Advances in glass production processes require systems with faster production lines (from 5 m/s up to 10 m/s and over) and high accuracy in defects detection Linear scan cameras with a higher sampling rate must be used to ensure that detection accuracy is kept constant or increased when the Fast Blob and Air Line Defects Detection for High Speed Glass