Ring roller mill counterweight function

Tabletype ring rolling machine for 500 mm rings

KFRWt is an acronym standing for semiautomated Kreuser springring rolling mill The KFRWt features four rolling stations arranged on a turntable Each station is equipped with a centering arm, a mandrel roll and roll table The turntable surrounds a driven main roll Its axis and the 2017年4月26日 Ring roller mill is mainly used for the ultrafine grinding of calcite, dolomite, limestone, marble, wollastonite and other minerals Taking calcite as an example, the grinding The application of ring roller mill in the processing of nonmetallic KFRWt is an acronym standing for semiautomated Kreuser springring rolling mill The KFRWt features four rolling stations arranged on a turntable Each station is equipped with a centering Tabletype ring rolling machine for 500 mm ringsRoller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and Roller Mill Springer

Raymond Roller Mill airswept vertical ringroll

The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies limestone, clay, minerals and The ultrafine roller mill drives the main shaft to rotate through the transmission device The upper end of the main shaft is connected to the rotor frame The frame is equipped with an auxiliary Ring Roller Mill ALPA Powder Equipment2006年7月3日 A model machine with extensive flexibility has been designed to explore innovation in ring rolling, with the intention of developing ring rolling machines which can The design of a flexible model ring rolling machine2015年8月1日 Radial–axial ring rolling (RARR) is a metalforming process for manufacturing seamless annular forgings, which are accurately dimensioned and have circumferential grain Setup of radial–axial ringrolling process: Process worksheet and

.jpg)

Planning and simulation of the ring rolling process for improved

1993年4月1日 Rolling of rectangular rings often leads to flow related defects such as fish tail or dog bone This paper presents a computer aided program, ERCRNGROL, for the planning 2019年2月6日 RadialAxial Ring Rolling (RARR) is an industrial forging process for making strong, seamless metal rings Conventionally, rings are made circular with constant cross Control of ring rolling with variable thickness and curvature2023年7月4日 'Roller Mill' published in 'The ECPH Encyclopedia of Mining and Metallurgy' Skip to main content Advertisement Account Menu Find a journal The Raymond mill is mainly composed of the plumblossom rack, the roller, the grinding ring, the blade, the feeding section, the return windbox, the discharge section, etcRoller Mill SpringerLinkRaymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsRAYMOND® ROLLER MILLS Thomasnet

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant size reduction equipments and it is defined by breakage distribution functionChina Ring Roller Mill wholesale Select 2024 high quality Ring Roller Mill products in best price from certified Chinese Roller Flour Mill manufacturers, Three Roller Machine suppliers, wholesalers and factory on MadeinChinaRing Roller Mill MadeinChina2023年6月3日 Function of Pellet Mill Roller Shells Pellet mill roller shells play a critical role in the pelletizing process, Ring Die Buying Guide 2024:5 Minutes to Learn Everything JinDing Machinery has been manufacturing feed machine parts for over 30 yearsPellet Mill Roller Shells: All You Want to Know JD Ring Die2013年5月15日 Exception handling • 21 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller, resulting in mechanical milling; when into the Vertical raw mill pradeep kumar PPT SlideShare

.jpg)

Operational parameters affecting the vertical roller mill

Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGate2013年3月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Cements ground in the vertical roller mill fulfil the quality Ring Roller Grinding Mill Benefits 1 High powder fineness process, the powder fineness can be adjusted between 3002500 mesh; 2 High capacity, there are 5 models dolomite powder making machine in Shanghai Clirik, the highest capacity can up to 45 t/h; 3 Environment friend, Clirik HGM dolomite powder making machine id environment friendly, it was popularity by our Ring Roller Grinding Mill2009年1月31日 Download Citation Grinding process within vertical roller mills: Experiment and simulation Based on screening analysis, laser size analysis, grindability and rigidity tests of samples Grinding process within vertical roller mills ResearchGate

.jpg)

Investigations into the movement of milled medium in the bowl of a ring

2009年4月4日 In order to observe and register the above interrelations, a 1:4 scale model of an RPtype ringroller mill was constructed, including a measurement system for determining the thickness of the bulk material as a function of its radius The model allowed experiments to be performed using a wide range of operational parameters of the mill 2also function to prevent the rolling elements from falling out Cages include pressed cages pressed out of metal plating, precut machined cages, and resin formed cages 5 Spherical roller Outer ring Shaft washer Housing washer Ball Bearing bore diameter Bearing single outside diameter BearingROLLING BEARINGS HANDBOOK NTN Americas超细辊压磨通过传动装置带动主轴转动,主轴的上端连接着转子架,架上装有辅轴,辅轴上装有磨轮。当主轴旋转时,辅轴随之旋转,辅轴上的磨轮不仅围绕主轴进行公转,同时又围绕各自的辅轴作自转。辊压磨 埃尔派粉体科技有限公司The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximatelyRaymond Roller Mill airswept vertical ringroll

.jpg)

Roller Mills Vs Hammer Mills Midwest Hardfacing

3 天之前 Maintaining roller mills is crucial for optimal performance and longevity Here are the top five maintenance tips: Regular Lubrication: Ensure proper lubrication of bearings and moving parts according to manufacturer recommendations to prevent friction and wear Routine Inspection: Regularly inspect rolls, bearings, shafts, gears, and supports for wear, damage, or Roller grain mills are an alternative to traditional millstone arrangements in gristmills Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling Transmission device connects with main shaftRoller mill ALPA Powder TechnologyGKH ring roller mill is a new type of superfine grinding equipment developed by our company with years of research and development and combining the advantages of Ring Roller Mill on the market GKH ring roller mill has the characteristics of high output, low energy consumption, reduced production cost, easy maintenance, etc It is a ideal model of domestic dry superfine Ring roller mill manufacturers Guilin Mining Machinery Co, LtdΦ9500mm Ring Rolling Mill The Φ9500 ring rolling mill is the world’s largest ring forging equipment capable of manufacturing 9 meters wide, 28 meters tall and 60 tons large ring forging products It has an extraordinary productivity for ring forging products that account for over 50% of the opendie forging market SCM태웅 홈 >FACILITIES>RING ROLLING MILL TAEWOONG

Nozzle ring assembly for a roller mill Google Patents

2017年9月6日 A nozzle ring assembly for use around a circular grinding path of a roller mill of the kind comprising a grinding table (1) which is rotatable about a vertical axis, and grinding rollers (2) urged against the grinding table The nozzle ring assembly comprises a nozzle ring (8) with circumferentially spaced guide vanes (17) for directing air, in use, over the grinding path in a The general main roll is a simple cylindrical shape, but the main roll for producing a profile ring with a complicated sectional shape varies depending on the product shape 2 Functions of main roll The main roll is the most important part of the ring mill The main roll is the reference point for measuring the dimensions of the ringThe structure and function of the main roll in the ring rolling The RM5 ring roller is a three driven roll bender that allows bending on either side of the bottom roll to give you more radius options Mills Lathes Accessories Drill Press Tooling Accessories; Special Function Bead Ring Roller (RM5) Baileigh2024年11月30日 Horizontal roller mills are often compared with vertical roller mills, and they boast several advantages: Better particle size distribution: The horizontal arrangement can lead to a more consistent grind Lower initial investments: Sometimes they are more economical when it comes to capital expenditure Flexible operation: Skilled operators can adjust horizontal mills Exploring the Different Types of Roller Mills

.jpg)

VERTICAL ROLLER MILLS AMCL

3+3 system of Main Roller and Sub Roller for Cement and Slag grinding As a feature of UBE’s sub rollers, they are designed to generate sufficient amount of load and are positioned near the dam ring on the circumference of the table Flat Table Liner And Conical Type Roller Tires Reduce abrasion and extend liners longevity Swing leverVEVOR Rolling Mills 3"/76mm Jewelry Rolling Mill Machine Gear Ratio 1:25 Wire Roller Mill 017mm Press Thickness Manual Combination Rolling Mill for Metal Jewelry Sheet Square Semicircle Pattern Visit the VEVOR Store The plastic ring band is simple for storageVEVOR Rolling Mills 3"/76mm Jewelry Rolling Mill Machine Gear 2018年8月7日 Buy Manual Rolling Mill Machine 3" Roller Manual Combination Rolling Mill Flatten Machine Ring Measurement Tool, MultiFunctional Jewelry Making Tool B05N 1 offer from $8999 YOOPAI D1 4in1 Laser Rotary Roller, Suitable for Most Frametype Laser Engraving Machines, with 2 Types of Claws and Pins, Manual Rolling Mill Machine 3" Roller Manual Combination Rolling Mill 2020年12月13日 Functions of ring frame: Hardness level of top back roller 80° 85° shore and 63° 65° shore at top front roller Draft and production of ring spinning mill (section wise): Section name Production heads/ machine Draft Production/ machine/hr(kg) Product nameRing Spinning Machine: Drafting System, Different Parts and Functions

7TOCS.jpg)

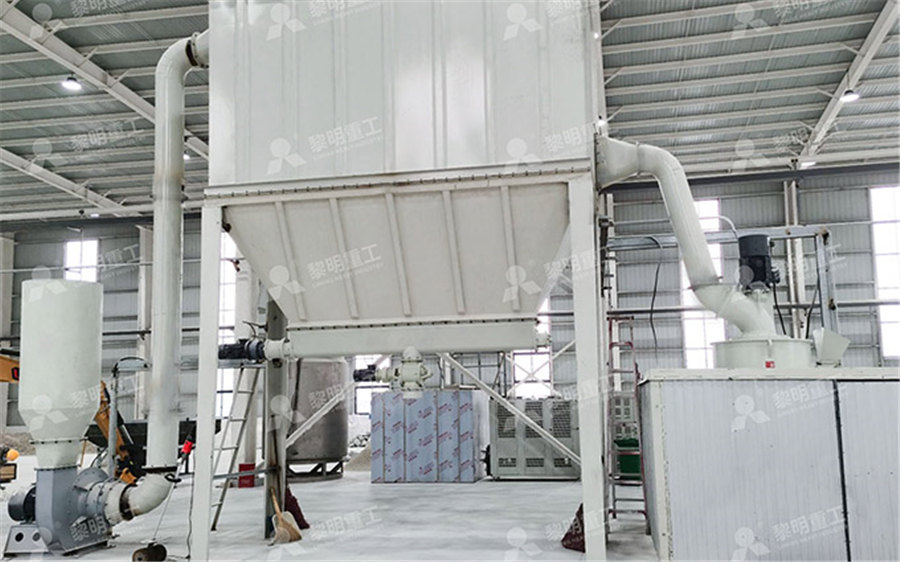

RLM Ring Roller Mill ALPA Powder Technology

Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grinding Builtin classifying wheel, available D50:2~45μm Compared with Raymond mill or ball mill, finer powder, lower operating cost Suitable for ultrafine processing of nonmetallic minerals such as calcium carbonate2022年4月30日 The main process equipment of 1580 hotrolled strip production line are: two threestage regenerative walking furnaces, postfurnace dephosphorization, one fourhigh reversible roughing mill, coil box, fine phosphorus removal, and seven fourhigh finishing mills , Layer cooling roller table, three downcoilers with three auxiliary rollers, walking beam transport Analysis on the Quality of Hot Rolled Coils LMM GROUP mill Function grading Pattern ring Description The Cross Ring Roller Range is manufactured in widths from 3 meters to 122 meters All Cross Rollers are fitted with custom manufactured steel rings as standard Cast iron rings can be fitted also upon barley mill 6000 roller mobile grain mill 9000 roller mobile See all Cross Agricultural Grading roller Cross Agricultural Engineering ring2019年6月10日 My FIL saved this from the dumpster and gave it to me When he first described it I was hoping it was a ring roller, but only has 2 wheels I figured out that its a Cavallin 120mm Rolling Mill Its used by jewelers for forming thin stock and bar (link) Cavallin is Rolling mill uses/thoughts? The HobbyMachinist

Roller Mill SpringerLink

2023年7月4日 'Roller Mill' published in 'The ECPH Encyclopedia of Mining and Metallurgy' Skip to main content Advertisement Account Menu Find a journal The Raymond mill is mainly composed of the plumblossom rack, the roller, the grinding ring, the blade, the feeding section, the return windbox, the discharge section, etcRaymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsRAYMOND® ROLLER MILLS Thomasnet2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant size reduction equipments and it is defined by breakage distribution function(PDF) Performance Evaluation of Vertical Roller Mill China Ring Roller Mill wholesale Select 2024 high quality Ring Roller Mill products in best price from certified Chinese Roller Flour Mill manufacturers, Three Roller Machine suppliers, wholesalers and factory on MadeinChinaRing Roller Mill MadeinChina

.jpg)

Pellet Mill Roller Shells: All You Want to Know JD Ring Die

2023年6月3日 Function of Pellet Mill Roller Shells Pellet mill roller shells play a critical role in the pelletizing process, Ring Die Buying Guide 2024:5 Minutes to Learn Everything JinDing Machinery has been manufacturing feed machine parts for over 30 years2013年5月15日 Exception handling • 21 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller, resulting in mechanical milling; when into the Vertical raw mill pradeep kumar PPT SlideShareRequest PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill 2013年3月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Cements ground in the vertical roller mill fulfil the quality

.jpg)

Ring Roller Grinding Mill

Ring Roller Grinding Mill Benefits 1 High powder fineness process, the powder fineness can be adjusted between 3002500 mesh; 2 High capacity, there are 5 models dolomite powder making machine in Shanghai Clirik, the highest capacity can up to 45 t/h; 3 Environment friend, Clirik HGM dolomite powder making machine id environment friendly, it was popularity by our 2009年1月31日 Download Citation Grinding process within vertical roller mills: Experiment and simulation Based on screening analysis, laser size analysis, grindability and rigidity tests of samples Grinding process within vertical roller mills ResearchGate