Technical parameters of industrial grinding mill

.jpg)

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

The IsaMill is a horizontal stirred mill with sizes up to 3 m3 chamber net volume and 1120 kW The mill provides the technical options to vary process parameters like airflow, mass flow, Operational parameters affecting the vertical roller mill performanceOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS Several energy OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLSGrinding in ball mills is an important technological process applied to reduce the size of Grinding in Ball Mills: Modeling and Process Control Sciendo

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill 2024年1月17日 This paper presents an overview of the regrind circuits in Brazil that operate with vertical mills and the results of industrial surveys at selected vertical mill circuitsParameters for the Grinding Process in Vertical Mills 1993年12月1日 To apply these source signals to monitoring of grinding parameters, industrial Monitoring grinding parameters by signal measurements for an Technical exploitation parameters of grinding rolls work in flour mill Res Agr Eng, 60 (Special Technical exploitation parameters of grinding rolls work in flour mill

Experimental observations of mill operation parameters on

The kinematic of the mill contents in wet grinding is influenced by a range of parameters such Technical exploitation parameters of grinding rolls work in flour mill Res Agr Eng, 60 (Special Issue): S92–S97 The proposed research paper analyses power consumption in grinding rolls of a flour mill The observed mill has 15 grind ing passages The hourly efficiency of grinding roll on the first passage is 3,00672 kg/h The specific Technical exploitation parameters of grinding rolls work in flour millSimulation operations were performed using grinding parameters (A, b, ta, Wi), operating constraints (plant capacity, d80 of the hydrocyclone overflow and ability to work for clayey minerals Specifications of industrial ball mills (PBM SBM)The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic Process

Effect of Milling Parameters on DEM Modeling of a Planetary Ball Mill

2023年1月1日 The relative motion and collision between grinding media in a wetstirred accelerator mill are modelled using the discrete element method (DEM) coupled with computational fluid dynamics (CFD)2013年5月1日 The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of hydrated lime and the product Effect of ball mill grinding parameters of hydrated lime fine grinding Drivers of grinding energy transfer to ore in ball mills • Charge density –charge shape and liner design • Charge surface area • Pulp density rheology • Media mass • Classifier efficiency How can we increase the grinding surface area? 1 Increase the grinding surface • Smaller ball media, or • Different media shape 2Rethinking Grinding Efficiency in Ball MillsThe grinding roller limit device is adopted to avoid the severe vibration of the mill due to material breaking Adopting a new grinding roller sealing device, the sealing is reliable, and there is no need for a sealing fan, which further reduces the oxygen content in the grinding mill and has excellent explosion suppression performanceHLMX Superfine Grinding Mill

Analysis on Technical Progress of Grinding Mill CSDN博客

2012年2月6日 It’s been over 50 years since the first industrial mill, the grinding mill come out, featuring of fine and ultrafine grinding mill Looking back, the historical progress are with rapid technological change and updated equipment innovation, but the most notable signs attribut to following two aspects:【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC MachineTechnical exploitation parameters of grinding rolls work in flour mill Res Agr Eng, 60 (Special Issue): S92–S97 The proposed research paper analyses power consumption in grinding rolls of a flour mill The observed mill has 15 grind ing passages The hourly efficiency of grinding roll on the first passage is 3,00672 kg/h The specific Technical exploitation parameters of grinding rolls work in flour mill2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the study was to analyze and evaluate A study of operating parameters of a roller mill with

.jpg)

Technical specifications of vertical roller coal mill

As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperature2021年6月29日 parameters on a realtime industrial scale The feed to the ball Five speed levels used in closed cycle grinding mill are 200, 400, 600, 800 and 1000 rpmEffects of Mill Speed and Air Classifier Speed on The process parameters used for these experiments of a typical industrial wet ball mill is specified in the Table 1 (a) (b) Fig 1(a), (b); Position of accelerometer sensors on industrial Ball Parameters of Industrial Ball Mill Parameters Value2021年6月17日 Abstract The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative contact energy This paper provides a new liner parameter design and optimization method, which offers theoretical guidance for the optimization design of liner parametersPARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersConsult NETZSCH Grinding Dispersing's entire Atlas Vertical Roller Mill catalogue on DirectIndustry Page: 1/4 Exhibit with us {{>currencyLabel}} Back {{>currenciesTemplate}} Classifier SCIROCCO Type Sizes not related with mill sizes Classifier BARAT Type All technical data are subject to changes DIMENSIONAL DRAWING Atlas Vertical Roller Mill NETZSCH Grinding DispersingCondition in one of the grinding chambers of the mill Results of Optimization The graphical analysis presented in Figure 2 represents progress of grinding along the length of the mill after optimizing the grinding process rogress of grinding is clearly visible in Desired p the graphs Figure 2: Analysis of longitudinal samplesOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLSPowder Technology 208 (2011) 121–127 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w e l s ev i e r c o m / l o c a t e / p ow t e c Optimization of some parameters of stirred mill for ultrafine grinding of refractory Au/Ag ores Oktay Celep a, Nevzat Aslan b, İbrahim Alp a,⁎, Gökhan Optimization of some parameters of stirred mill for ultrafine grinding

.jpg)

Technical Note Effect of ball size change on the performance of

The makeup ball characteristics of each mill are shown in Table 1 In ball mill No2, 75% 80mm and 25% 60mm balls were charged The average weight of the balls in each mill is about 300 tons The grinding circuit of the plant is shown in Fig 1 Ball Mill Pump Cyclone Water Water Feed Figure 1 The grinding circuit of the Sarcheshmeh copper mineGypsum grinding mill is a common industrial powder making equipment It can be used in many different industries, such as construction, ceramic, paint, paper, etc HOME; such as construction, ceramic, paint, paper, etc The technical specifications and parameters of gypsum grinding mill are very important for its proper operationGypsum ginding mill technical specifications parameters2003年10月3日 The first 90 years of the last century generated a considerable volume of technical literature on the subject of grinding mill power and its predictionGrinding mills: how to accurately predict their 2014年12月31日 The proposed research paper analyses power consumption in grinding rolls of a flour mill The observed mill has 15 grinding passages The hourly efficiency of grinding roll on the first passage is Technical exploitation parameters of grinding rolls work in flour mill

Effect of operating parameters on fine particle grinding in a

2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different demand for industrial mill has been reported as 20% more as compared to the lab scale mill In comparison of industrial and lab scale mills for 28day compressive strength, the increase of almost 10 MPa has been reported for the industrial mill [2] The optimization in the processing parameters could be equally useful for other millEffects of Mill Speed and Air Classifier Speed on Performance of 2020年8月12日 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureAn investigation of performance characteristics and energetic 2016年1月1日 The wear of balls used during a grinding process is considered one of the losses that cause an increase in the operating cost allocated to the ball mill [21]A comparison of wear rates of ball mill grinding media

.jpg)

Semiautogenous grinding (SAG) mill liner design and development

in variable speed mills, this may be achieved by reducing mill speed; and in both cases this may be achieved by design by increasing the lifter face angle Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (eg, a 34ftdiameter mill shell would have 68 shell lifters)HGM Threering Grinding Mill Feed size: 020mm Capacity: 0525t/h Power: 55315kw YGM High Basic technical parameters of LM vertical roller mill (nonmetallic mining industry) Model LM1300K If you want to know more about our crushers and industrial grinding equipmentGRINDING MILLZhengzhou Vanguard Machinery Technology Based on nearly 20 years mill research and operation experience, LUM Ultrafine Vertical Mill has been developed as the equipment for ultrafine powder grinding and separation Its production introduces talents in ultrafine powder production and machine manufacturing industry, and absorbs the technologies and experience of ultrafine vertical mills from Germany, Japan and LUM Ultrafine Vertical MillVertical Powder GrinderClirikTechnical exploitation parameters of grinding rolls work in flour mill Res Agr Eng, 60 (Special Issue): S92–S97 The proposed research paper analyses power consumption in grinding rolls of a flour mill The observed mill has 15 grind ing passages The hourly efficiency of grinding roll on the first passage is 3,00672 kg/h The specific Technical exploitation parameters of grinding rolls work in flour mill

.jpg)

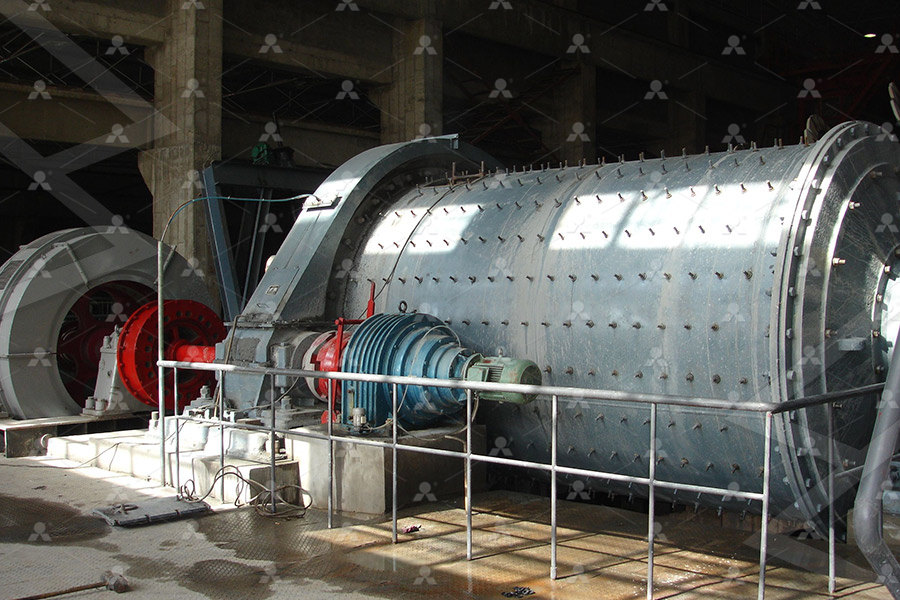

Specifications of industrial ball mills (PBM SBM)

Simulation operations were performed using grinding parameters (A, b, ta, Wi), operating constraints (plant capacity, d80 of the hydrocyclone overflow and ability to work for clayey minerals The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic Process2023年1月1日 The relative motion and collision between grinding media in a wetstirred accelerator mill are modelled using the discrete element method (DEM) coupled with computational fluid dynamics (CFD)Effect of Milling Parameters on DEM Modeling of a Planetary Ball Mill2013年5月1日 The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of hydrated lime and the product Effect of ball mill grinding parameters of hydrated lime fine grinding

Rethinking Grinding Efficiency in Ball Mills

Drivers of grinding energy transfer to ore in ball mills • Charge density –charge shape and liner design • Charge surface area • Pulp density rheology • Media mass • Classifier efficiency How can we increase the grinding surface area? 1 Increase the grinding surface • Smaller ball media, or • Different media shape 2The grinding roller limit device is adopted to avoid the severe vibration of the mill due to material breaking Adopting a new grinding roller sealing device, the sealing is reliable, and there is no need for a sealing fan, which further reduces the oxygen content in the grinding mill and has excellent explosion suppression performanceHLMX Superfine Grinding Mill2012年2月6日 It’s been over 50 years since the first industrial mill, the grinding mill come out, featuring of fine and ultrafine grinding mill Looking back, the historical progress are with rapid technological change and updated equipment innovation, but the most notable signs attribut to following two aspects:Analysis on Technical Progress of Grinding Mill CSDN博客【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC Machine

Technical exploitation parameters of grinding rolls work in flour mill

Technical exploitation parameters of grinding rolls work in flour mill Res Agr Eng, 60 (Special Issue): S92–S97 The proposed research paper analyses power consumption in grinding rolls of a flour mill The observed mill has 15 grind ing passages The hourly efficiency of grinding roll on the first passage is 3,00672 kg/h The specific