Limestone desulfurizer equipment

Summary of research progress on industrial flue gas

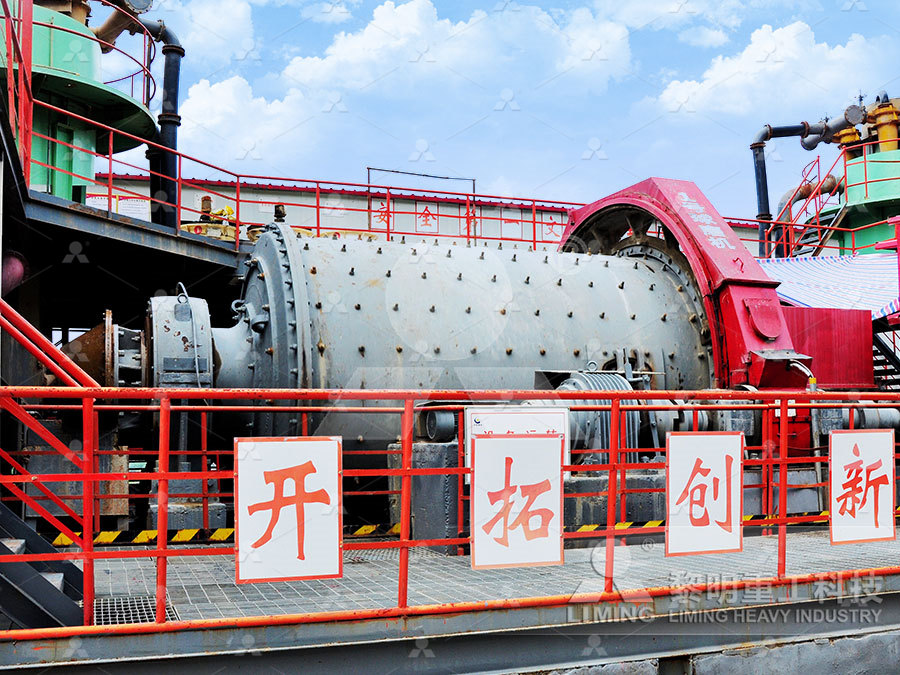

2022年1月15日 Infurnace calcium injection desulfurization technology sends limestone powder or lime powder gas into the furnace Under high temperature conditions, calcium carbonate Note: we completed a process of lime stone powder making, provide limestone powder desulfurization preparation technology and required equipments The completed process required equipment includes vibrating feeder, jaw crusher, Limestone Flue Gas Desulfurization System SupplierMitsubishi Power effectively contributes to the prevention of air pollution through its wet limestonegypsum FGD process and seawater FGD process, and both processes can treat a large range Mitsubishi Power Flue Gas Desulfurization (FGD) PlantsLimestone is a desulfurizer with high desulfurizing efficiency, wide sources, rich resources and low price It is the main desulfurizer used in limestone gypsum flue gas wet desulfurization The Equipment Introduction: Grinding Mill Production Line For

Limestonewet desulfurization equipment Leadermro Cross

Limestone or lime is used as the desulfurization absorbent The limestone is crushed and ground into powder and mixed with water to form an absorption slurry When lime is used as the Limestone/ gypsum dry process/ semi dry process/ wet process desulphurization is a process to desulfurize flue gas It has the advantages of mature technology, low investment, high Power Plant DesulfurizationLime is more reactive than limestone, and requires less capital equipment SO 2 removal efficiencies using lime scrubbers range from 95 to 99 percent at electric generating plants HCl Flue Gas Desulfurization LimeOverview Column mill limestone powdering system is currently the five major domestic power groups and foreign power groups of CFB boiler power plant desulfurizer preparation system Limestone Grinding System For Infurnace Desulfurization For CFB

.jpg)

Flue Gas Desulfurization Yokogawa Canada

Wet flue gas desulfurization or scrubber systems are very effective in reducing sulfur dioxide (SO2) emissions caused by coal combustion boilers The flue gas discharged from the boiler is fed into the absorber, where a mixture of water 2021年2月1日 Compared with limestonebased wet flue gas desulfurization (WFGD), magnesiabased WFGD has many advantages, but it is not popular in China, due to the lack of good wastewater treatment schemesLimestoneGypsum Wet Flue Gas Desulfurization 2020年12月1日 To reduce the cost of the current commercial desulfurization and eliminate effluents, the MgObased desulfurizer fixed bed desulfurization tests were carried out in a dry environment(PDF) Experiment and Mechanism Analysis of1Damage Analysis of Desulfurizer Equipments for Synthesis Gas Plant and Its Prevention Measures合成气装置脱硫设备损伤分析及治理 2The money will help pay for desulfurization equipment for large, coalfired steel plants in the provincial capital, Taiyuan这些资金将用来为省会太原的燃煤钢厂购买大量的脱硫设备。脱硫设备,desulfurization equipment英语短句,例句大全

.jpg)

Experiment and Mechanism Analysis of Desulfurization with a

2020年12月12日 21 Scanning Electron Microscopy Studies To explore the change of the surface morphology of desulfurizers (before and after desulfurization), sampling I (fresh desulfurizer which unabsorbed SO 2), sampling II (desulfurizer which was at the outlet and absorbed SO 2), and sampling III (desulfurizer which was at the inlet and absorbed SO 2) 2022年7月14日 In the formula, η SO2 is SO 2 removal efficiency; C in is that concentration of SO 2 at the gas inlet, ppm; C out is the SO 2 concentration at the gas outlet, ppm The properties of carbide slag before and after the experiment were characterized and analyzed The equipment and test conditions were as follows: Xray fluorescence spectrometer (XRF, PANalytical Axios) Desulphurization mechanism and engineering practice of carbide 2024年9月11日 LM vertical rod mill has remarkable effect on desulfurizer treatment in power plant endangers animal and plant growth and human health, and corrodes metal equipment the formation of SO2 during combustion At present, the most widely used desulfurization method in the world is the limestonegypsum desulfurization methodLM vertical rod mill has remarkable effect on desulfurizer Desulfurizer: lime/hydrated lime Advantage 1 The process is simple 2 The equipment is basically free from corrosion, abrasion, scaling and wastewater discharge 3 It occupies less land, saves space, and has low equipment investment Defect 1 It is necessary to use lime with high purity and activity as desulfurizer 2Desulfurization millvertical millRaymond milllimestone mill

LD type limestone powder continuous conveyor Pneumatic

The equipment uses high pressure Roots blower (or compressed air) for power gas source, to achieve continuous transmission Used for the electroplating of boiler fuel mixed with limestone (desulfurizer) Limestone powder delivery system procedures using automatic control procedures, and communication with the DCS interfaceTo comply the regulation, the sulfur dioxide (SO2) concentration should be reduced to designated standard of emission which was stated in the regulation It causes many coal fired power plant (CFPP) need to procure a new or upgrade their desulfurization equipment In this study the desulfurization method focused on the usage of Limestone forced oxidation (LSFO) The study Effect of Flue Gas Oxygen Content to GasGas Heater Requirement 2024年4月19日 Limestone gypsum wet flue gas desulfurization process 2 Magnesium oxide desulfurization process The basic principle of magnesium oxide desulfurization is similar to that of limestone (lime) method, that is, the SO2 in the flue gas is absorbed by magnesium oxide slurry, which mainly generates trihydrate and polyhydrate magnesium sulfite, and then generates 4 Flue Gas Desulfurization Process You Should Never MissE3S Web of Conferences, 2019 The paper presents data concerning the influence of ammonia on wet flue gas desulfurization (WFGD) absorber Paper presents preliminary results of an industrial scale study on WFGD absorber, Optimization of Limestonegypsum Wet Flue Gas

.jpg)

Flue Gas Desulfurizer mass and energy balance in 300 MW class

To meet SO2 emission new regulation, Indonesian CFSPP shall be upgraded with a new desulfurizer equipment (if not there before) or increase the capture ability (existing equipment) SO2 concentration required in the previous regulation was maximum 750 mg/Nm 3 , and then revised with the new regulation with the numbers of 550 mg/Nm 3 (existing power plant) and Before flue gas desulfurization was installed, the emissions from the Four Corners Generating Station in New Mexico contained a significant amount of sulfur dioxide The G G Allen Steam Station scrubber (North Carolina) Fluegas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide (SO 2) from exhaust flue gases of fossilfuel power plants, and from the Fluegas desulfurization WikipediaFor example, limestone with Cao > 54% is Dali Petrochemical due to its high purity, not easy to grind and strong chemical stability, so it is not suitable to be used as desulfurizer (2)Limestone particle size (fineness) The particle size of limestone directly affects the reaction rateNews Desulfurization Limestone Grinding Mill Sale Limestone 2022年3月1日 The carbide slag (generated from a PVC factory) and limestone (used in a coalfired power plant) were used as two kinds of desulfurizer, whose compositions are shown in Table 1It illustrates that calcium resources are abundant in carbide slag, which also contains a small number of impurities such as SiO 2 and Al 2 O 3The main component of CaO is 7789%, High efficiency desulfurization behavior by the sustainable low

Summary of research progress on industrial flue gas

2022年1月15日 Because the desulfurizer used in wet flue gas desulfurization is liquid, an and the desulfurization rate is high Wet desulfurization technology includes limestonegypsum desulfurization in China Excessive sulfur impurities in bauxite have significant impact on the Bayer process, such as corrosion of equipment and Wet flue gas desulfurization or scrubber systems are very effective in reducing sulfur dioxide (SO2) emissions caused by coal combustion boilers The flue gas discharged from the boiler is fed into the absorber, where a mixture of water and pulverized limestone is sprayed on the flue gas The limestone slurry reduces sulfur emissions by absorbing the SO2 contained in the flue Flue Gas Desulfurization Yokogawa CanadaThe commonly used wet desulfurizer is limestone, which is expensive (Xu et al 2019) The carbide slag has the advantages of wide sources, low price, and similar active ingredients with limestone, so that the carbide slag can be used for replacing the traditional limestone desulfurization to reduceDesulphurization mechanism and engineering practice of carbide It is the main desulfurizer used in limestone gypsum flue gas wet desulfurization The smaller the particle size of limestone, the better the absorption of sulfur dioxide The fineness of commonly used limestone desulfurizer is 250 mesh or 325 mesh (45 μ m), and 325 mesh limestone powder has better desulfurizing effectEquipment Introduction: Grinding Mill Production Line For Limestone

Preliminary Study of Dry Sorbent Injection and Limestone Forced

Abstract: To meet SO 2 emission new regulation, Indonesian CFSPP shall be upgraded with a new desulfurizer equipment (if not there before) or increase the capture ability (existing equipment) SO 2 concentration required in the previous regulation was maximum 750 mg/Nm 3, and then revised with the new regulation with the numbers of 550 mg/Nm 3 (existing power AGICO Cement International Engineering Co,Ltd (AGICO Cement), situated in a historic capital and the hightech development industrial assembly plant in Anyang City,specializes in the design,modification,ignition,and production services of energyefficient and ecofriendly vertical shaft kilns The company also manufactures related main equipment and provides kiln Rotary kiln for sale, Limestone calcination, Factory for Vertical lime Why Limestone Mill Is An Important Equipment to Produce Desulfurizer 11:01:07 Desulphurization process develops rapidly in recent years, and has become one of the most popular chemical treatment process in the world There are over two hundred kinds until now, of which the most practical and mature is the limestone desulfurizationWhy Limestone Mill Is An Important Equipment to Produce DesulfurizerUsing limestone powder as desulfurizer of limestone gypsum wet desulphurization process About gypsum wet desulphurization process Limestone powder by solid liquid two phase of dissolving reaction, the reaction rate is Limestone Flue Gas Desulfurization System Supplier

.jpg)

A brief review on flue gas desulfurization gypsum recovery toward

In addition, plants need large quantities of limestone as a desulfurizer It is worth noting that Cl and F are enriched in FGDG from flue gas 115,116 The issues of equipment corrosion by Cl and F should be taken into consideration in practical useThe chemical principle of limestone powder as desulfurizer In the combustion of coal burning a certain proportion of limestone powder, developed desulfurization milling equipment and technology, high sulfur coal desulfurization rate can be more than 90%, desulfurization rate of low sulfur coal can be more than 95% The process is: Limestone Mill for Desulfurization,Limestone Equipment forAbstract: To meet SO 2 emission new regulation, Indonesian CFSPP shall be upgraded with a new desulfurizer equipment (if not there before) or increase the capture ability (existing equipment) SO 2 concentration required in the previous regulation was maximum 750 mg/Nm 3, and then revised with the new regulation with the numbers of 550 mg/Nm 3 (existing power Preliminary Study of Dry Sorbent Injection and Limestone Forced Liming Heavy Industry is the only supplier of limestone desulfurizer grinding equipment for this project It provides 4 sets of MTW215 European Type Grinding Mill for processing limestone powder with two particle sizes used inside and outside the furnaceLimestone Grinding Plant LIMING (Shanghai)

.jpg)

KRA Petro Cokes Combustion System with Hybrid Desulfurizer

The present invention provides a petroleum coke combustion system including a semidry reactor The petroleum coke combustion system comprises: a petroleum coke supply part and a refined oil supply part for supplying petroleum coke and refined oil; a combustion furnace and a boiler including a combustion furnace for burning petroleum coke and desulfurizing the petroleum The utility model provides a limestone add the equipment in the large granule lime stone when too much, cause the filter screen to take place to block up easily, the inner wall of equipment can bond at most has the desulfurizer, when the accumulational too much of desulfurizer, then can influence the reaction effect of desulfurizer and solution and the desulfurizer is thick than, the CNU Production equipment of highefficiency desulfurizer Why Limestone Mill Is An Important Equipment to Produce Desulfurizer Desulphurization process develops rapidly in recent years, and has become one of the most popular chemical treatment process in the world There are over two hundred kinds until now, of which the most practical and mature is the limestone desulfurizationWhy Limestone Mill Is An Important Equipment to Produce Desulfurizer2021年2月1日 Compared with limestonebased wet flue gas desulfurization (WFGD), magnesiabased WFGD has many advantages, but it is not popular in China, due to the lack of good wastewater treatment schemesLimestoneGypsum Wet Flue Gas Desulfurization

.jpg)

(PDF) Experiment and Mechanism Analysis of

2020年12月1日 To reduce the cost of the current commercial desulfurization and eliminate effluents, the MgObased desulfurizer fixed bed desulfurization tests were carried out in a dry environment1Damage Analysis of Desulfurizer Equipments for Synthesis Gas Plant and Its Prevention Measures合成气装置脱硫设备损伤分析及治理 2The money will help pay for desulfurization equipment for large, coalfired steel plants in the provincial capital, Taiyuan这些资金将用来为省会太原的燃煤钢厂购买大量的脱硫设备。脱硫设备,desulfurization equipment英语短句,例句大全2020年12月12日 21 Scanning Electron Microscopy Studies To explore the change of the surface morphology of desulfurizers (before and after desulfurization), sampling I (fresh desulfurizer which unabsorbed SO 2), sampling II (desulfurizer which was at the outlet and absorbed SO 2), and sampling III (desulfurizer which was at the inlet and absorbed SO 2) Experiment and Mechanism Analysis of Desulfurization with a 2022年7月14日 In the formula, η SO2 is SO 2 removal efficiency; C in is that concentration of SO 2 at the gas inlet, ppm; C out is the SO 2 concentration at the gas outlet, ppm The properties of carbide slag before and after the experiment were characterized and analyzed The equipment and test conditions were as follows: Xray fluorescence spectrometer (XRF, PANalytical Axios) Desulphurization mechanism and engineering practice of carbide

LM vertical rod mill has remarkable effect on desulfurizer

2024年9月11日 LM vertical rod mill has remarkable effect on desulfurizer treatment in power plant endangers animal and plant growth and human health, and corrodes metal equipment the formation of SO2 during combustion At present, the most widely used desulfurization method in the world is the limestonegypsum desulfurization methodDesulfurizer: lime/hydrated lime Advantage 1 The process is simple 2 The equipment is basically free from corrosion, abrasion, scaling and wastewater discharge 3 It occupies less land, saves space, and has low equipment investment Defect 1 It is necessary to use lime with high purity and activity as desulfurizer 2Desulfurization millvertical millRaymond milllimestone millThe equipment uses high pressure Roots blower (or compressed air) for power gas source, to achieve continuous transmission Used for the electroplating of boiler fuel mixed with limestone (desulfurizer) Limestone powder delivery system procedures using automatic control procedures, and communication with the DCS interfaceLD type limestone powder continuous conveyor Pneumatic To comply the regulation, the sulfur dioxide (SO2) concentration should be reduced to designated standard of emission which was stated in the regulation It causes many coal fired power plant (CFPP) need to procure a new or upgrade their desulfurization equipment In this study the desulfurization method focused on the usage of Limestone forced oxidation (LSFO) The study Effect of Flue Gas Oxygen Content to GasGas Heater Requirement

46.jpg)

4 Flue Gas Desulfurization Process You Should Never Miss

2024年4月19日 Limestone gypsum wet flue gas desulfurization process 2 Magnesium oxide desulfurization process The basic principle of magnesium oxide desulfurization is similar to that of limestone (lime) method, that is, the SO2 in the flue gas is absorbed by magnesium oxide slurry, which mainly generates trihydrate and polyhydrate magnesium sulfite, and then generates