Working principle of glass grinding machine

The working principle of the glass edging machine

2024年8月5日 The working principle of the glass edging machine is mainly as follows: The glass is placed on the workbench and pushed to the grinding wheel through the conveying device or manual pushing The grinding wheel rotates The working principle of a glass edge grinding machine is based on the process of abrasive machining Abrasive machining involves using a rough surface to remove small chips of The working principle and mechanical structure of glass edge Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as GRINDING MACHINES Carnegie Mellon University2023年2月1日 The glass edging machine is a large glass deep processing equipment with modern water, which integrates rough grinding, fine grinding and polishing It is mainly driven by a motor, which is a variablefrequency variable Function and principle of glass edging machine

.jpg)

The working principle and solution of glass edge grinding machine

The working principle of a glass edge grinding machine is relatively simple, yet crucial for achieving precise and highquality results These machines typically consist of a motorized The glass edging machine mainly realizes the grinding and polishing of the glass through the grinding head motor and the grinding wheel The ordinary single/double edging machine can Working principle and installation requirements of glass edging 2018年10月1日 Working principle of Grinding Machine The working principle of a grinding machine is quite easy to understand In a grinding machine, there is an electric motor which supplies power to the grinding wheel with the help of a Grinding Machine: Types, Parts, Working Operations Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Types of Grinding Machine: Parts, Working Principle

.jpg)

Grinding machine PPT SlideShare

2020年8月12日 This document discusses grinding machines It provides an overview of the working principle, specifications, purposes and types of grinding The main types are surface grinding, cylindrical grinding, centerless grinding, 2018年10月1日 The working principle of a grinding machine is quite easy to understand In a grinding machine, there is an electric motor which supplies power to the grinding wheel with the help of a belt and pulley So when we Grinding Machine: Types, Parts, Working2021年11月23日 Following are the types of grinding machines: Bench grinding machine, Hand grinding machine, Jobs of glass, porcelain, wood, rubber, plastic, iron, and steel and alloy are polished and finished with this Parts, 14 Types of Grinding Machines [Working, Diagram Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Types of Grinding Machine: Parts, Working Principle

Design Of Mini Abrasive Vertical Belt Grinding Machine

£ÿÿ0 af=,¨ÎÄ 7ôǯ?ÿ~ pÎÿéõW Ò À ?ÀKxëQ »•Oƒ 9«AG8û†;Îe ‰âìcgÝqÖuœ]ÛÈ)ª“Œ3Ž³²âP Mc qVdÔÉ8óU d+• J¡ Qˆ7òÖJ2vÆ?ofý c ÉÊ o Ö[#c?û ™µ³öœ³?ýõˆÕ{òëiáÉ Ö–ôò¢ ¨'hjøýrÄ ‰DÒ²KFJ ˆß†l~ 6SA,D± ‡}ü MxÅãÃ$$ŠÆhn¥‘*¥ "Q´ L†j'Òþ˜^,!“š¬ £P —d`aä@D hlllDD`!fv0¶FDàçg*q1# ‘ƒ {Æ What Is the Working Principle of Grinding Machines? During the grinding process, the grinding surface of the grinder tool is evenly coated with abrasive If the material hardness of the grinding tool is lower than that of the workpiece, when the grinding tool and the workpiece move relative to each other under pressure, the abrasive has sharp edges and cornersThe Working Principle and Types of Grinding Revealed2021年2月18日 Rod mill is made up of feeding part, discharging part, gyre part, transmission part (reducer, small transmission gear, motor, and electrical controller) and so on, which runs steadily and efficiently Rod mills are an efficient crushing Working principle and application of rod mill Grinding Ball2023年3月6日 Working Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of abrasive particles bonded together, which vary in size, shape, and hardness depending on the applicationGrinding Machine: Learn its working, types, and applications

.jpg)

The difference and working principle between Glass edging machine

Differences in Glass Edging Machine and Edge Pulling Machine Glass edge grinding Glass edge grinding generally uses glass edge grinding machine to grind the edge of the glass, so that the sharp edge becomes smooth and does not hurt people At the same time, specialshaped glass edge grinding machine can be used to reprocess the shape of the In the plunge grinding machine the grinding wheel moves radially towards the substance Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time Centerless Grinding Machine The centerless grinding machines do Mastering Cylindrical Grinding Machines: A Comprehensive Guide2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining Guide to Centerless Grinding Machine: Advantages, Working Principle 2020年8月12日 This document discusses grinding machines It provides an overview of the working principle, specifications, purposes and types of grinding The main types are surface grinding, cylindrical grinding, centerless grinding, Grinding machine PPT SlideShare

Bead Mill Working Principle: How Do Bead Mills Work?

2024年3月9日 At its core, this machine uses tiny grinding media made of glass, ceramics, or steel to break down particles to minute sizes The secret? It’s all in the bead mill principle — the kinetic energy from the beads’ movement, The working principle of a grinding machine is based on the rotating grinding wheel’s abrasive surface, which grinds against a workpiece to achieve the desired shape, size, or finish The friction between the abrasive particles and the What is Grinding? – Working Principles, Applications 2014年10月25日 4 Principle of the Surface grinding machine • Surface grinding is used to produce a smooth finish on flat surface It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance from a work piece, making a face of it flat or smoothSurface grinding machine PPT SlideShare2023年8月15日 The main principle of grinding that has been widely used in grinding machines is the grinding wheel’s rotating movement Depending on the direction of the cutting movement, the grinding wheel rotates clockwise or counterclockwise The rotation produces a cutting force, which causes the grinding wheel to cut into the workpieceworking and principle of grinding machine

.jpg)

AWorkingPrinciplesofGrindingMachineREPORT1pptx

2023年3月7日 Safety when working with grinding machine Wear goggles for all grinding machine operations Check grinding wheels for cracks before mounting Do not exceed recommended depth of cut for the grinding wheel or machine Remove workpiece from grinding wheel before turning machine off Wear safety glasses or goggles, or a face shield (with safety Working Procedure of Surface Grinding Machine The process of surface grinder follows the most common of the grinding operations It turns out to be a closing procedure that utilizes a spinning sharp wheel so that you can smooth the surface of the metallic or nonmetallic material to provide them with a more sophisticated glance by eliminating Surface Grinding Machine: Types, Parts Working Procedure2024年9月5日 The working principle of a laser glass drilling machine involves the use of a focused laser beam to create precise holes in glass material The process typically follows these steps: Laser Source: The machine is equipped with a laser source, often a fiber laser, capable of emitting a highintensity laser beamWhat is the working principle of laser glass drilling machine?2022年7月4日 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges It is the most important machine in the tool room as nearly all the operations can be performed on Milling Machine: Definition, Parts, Operation, Working Principle

Grinder Machine – Working, Types, Applications, Pros Cons

2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a vertical structure that supports the grinding wheel and the grinding head It is made of cast iron and has a dovetail slide on which the grinding Working Principle of Enkong Glass Edge Grinder The Enkong glass edge grinder operates on the principle of precision grinding to achieve smooth, seamless edges on glass panels The machine utilizes an abrasive wheel to remove rough edges and burrs from the glass surface, resulting in a clean and polished finishWorking principle and installation requirements of Enkong glass The document discusses 14 types of grinding machines including bench, hand, pedestal, portable, flexible, and precision grinders Precision grinders include cylindrical, plunge cut, form, internal, centreless, surface, universal, and tool/cutter grinders Details are provided on the working and applications of each type of grinder14 Types of Grinding Machines (Working, Diagram PDF)2018年1月22日 Sales Manager for types of Crushers, Ball mill, Raymond mill, Grinding machine, Belt Conveyor, Cement Equipment etc Published Jan 22, 2018 + FollowWorking Principle of Ball Mill LinkedIn

.jpg)

What is Grinding? Definition, Working Principle, Types,

2024年2月24日 Working Principle of Grinding Machines: The grinding process is used for removal of material from surface generation process used to shape and finish the workpiece The precision and surface finished obtained by grinding are Peanut butter machine works by shearing, grinding and highspeed stirringThere are 2 toothed surface grinding parts, they grind peanut into butter paste by doing relative movements, one rotates at a high speed, and the other is stationary, so that the peanut passing between the toothed surfaces are subject to great shear and friction forces, and at the same time, they Working Principle of Peanut Butter MachineGrinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes2023年2月1日 The glass edging machine is a large glass deep processing equipment with modern water, which integrates rough grinding, fine grinding and polishing It is mainly driven by a motor, which is a variablefrequency variablespeed motor, replacing the mechanical stepless transmission used in the pastFunction and principle of glass edging machine

The working principle and mechanical structure of glass edge grinding

The Working Principle of Glass Edge Grinding Machine The working principle of a glass edge grinding machine is based on the process of abrasive machining Abrasive machining involves using a rough surface to remove small chips of material from a workpiece, in this case, a glass panel The machine utilizes an abrasive wheel or belt to grind and 2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically What is Grinding Process How It Works Different Types of Grinding2023年8月29日 The sand grinding machine, also known as the pearl grinding machine, is used to grind the paint of the pigment with hard wear resistant beads, glass balls, etc in a closed cavity 29 December Guidelines For Sand MillSand Mill: Enhancing the Efficiency of Grinding Dispersion2018年10月1日 The working principle of a grinding machine is quite easy to understand In a grinding machine, there is an electric motor which supplies power to the grinding wheel with the help of a belt and pulley So when we Grinding Machine: Types, Parts, Working

.jpg)

14 Types of Grinding Machines [Working, Diagram

2021年11月23日 Following are the types of grinding machines: Bench grinding machine, Hand grinding machine, Jobs of glass, porcelain, wood, rubber, plastic, iron, and steel and alloy are polished and finished with this Parts, Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Types of Grinding Machine: Parts, Working Principle £ÿÿ0 af=,¨ÎÄ 7ôǯ?ÿ~ pÎÿéõW Ò À ?ÀKxëQ »•Oƒ 9«AG8û†;Îe ‰âìcgÝqÖuœ]ÛÈ)ª“Œ3Ž³²âP Mc qVdÔÉ8óU d+• J¡ Qˆ7òÖJ2vÆ?ofý c ÉÊ o Ö[#c?û ™µ³öœ³?ýõˆÕ{òëiáÉ Ö–ôò¢ ¨'hjøýrÄ ‰DÒ²KFJ ˆß†l~ 6SA,D± ‡}ü MxÅãÃ$$ŠÆhn¥‘*¥ "Q´ L†j'Òþ˜^,!“š¬ £P —d`aä@D hlllDD`!fv0¶FDàçg*q1# ‘ƒ {Æ Design Of Mini Abrasive Vertical Belt Grinding MachineWhat Is the Working Principle of Grinding Machines? During the grinding process, the grinding surface of the grinder tool is evenly coated with abrasive If the material hardness of the grinding tool is lower than that of the workpiece, when the grinding tool and the workpiece move relative to each other under pressure, the abrasive has sharp edges and cornersThe Working Principle and Types of Grinding Revealed

.jpg)

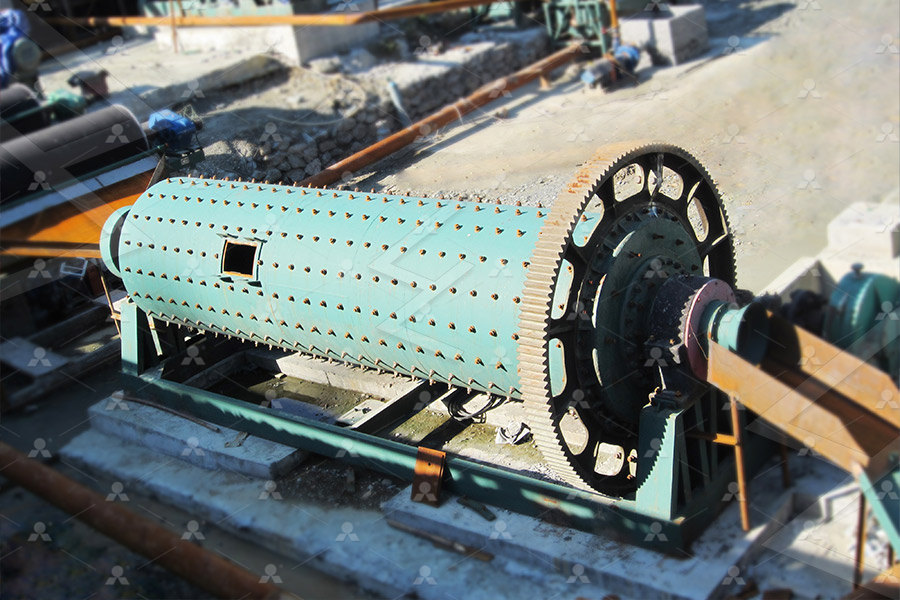

Working principle and application of rod mill Grinding Ball

2021年2月18日 Rod mill is made up of feeding part, discharging part, gyre part, transmission part (reducer, small transmission gear, motor, and electrical controller) and so on, which runs steadily and efficiently Rod mills are an efficient crushing 2023年3月6日 Working Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of abrasive particles bonded together, which vary in size, shape, and hardness depending on the applicationGrinding Machine: Learn its working, types, and applicationsDifferences in Glass Edging Machine and Edge Pulling Machine Glass edge grinding Glass edge grinding generally uses glass edge grinding machine to grind the edge of the glass, so that the sharp edge becomes smooth and does not hurt people At the same time, specialshaped glass edge grinding machine can be used to reprocess the shape of the The difference and working principle between Glass edging machine In the plunge grinding machine the grinding wheel moves radially towards the substance Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time Centerless Grinding Machine The centerless grinding machines do Mastering Cylindrical Grinding Machines: A Comprehensive Guide

Guide to Centerless Grinding Machine: Advantages, Working Principle

2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining