Is it costeffective to crush fine sand powder equipment

Types of Crushers: Choosing the Right One for Each

2024年7月17日 Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process Crushing is a multistage process that includes 2024年2月12日 Low Operating Costs: Sand making machines are energyefficient and have low maintenance requirements, contributing to costeffective operation Advanced Technology: Many modern sand making machines are Introduction of sand making machine application and 2024年10月22日 A complete sand making line typically involves four stages: crushing (primary and secondary), fine crushing and sand making, screening, and sand washing Each stage is A Comprehensive Guide to Sand Making Plants and Machines2023年2月23日 CostEffective: One of the main advantages of sand crushing machines is that they are costeffective These machines are designed to process large amounts of raw material quickly and efficiently, which means that A Comprehensive Guide to Sand Crushing Machines

.jpg)

Double Roller Crusher Machine For Sand Making

2024年9月6日 Is the sand produced by the roller sand making machine effective? Yes, it is effective The final sand has uniform particle size, low overcrushing rate, low needlelike 2021年5月21日 Vertical shaft impact crusher is the new generation of sand making equipment It is very costeffective and is one of the most popular sand making equipment on the market 4 Main Types Of Sand Making Machine On The Market2023年5月12日 Cubic finished product: No secondary processing is required, saving working time and cost Long service life and easy maintenance: Wearresistant liners on the grinding 6 Sand Making Machines and How to Choose the Best One2016年4月7日 A pitportable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face In modern plants, it is costeffective to use a Selecting the right type of crushing equipment Quarry

.jpg)

Types And Applications Of SandMaking Equipment

The VSI impact crusher, also known as VSI sandmaking machine, is the core equipment in the sand production line It crushes materials through highspeed rotating rotors and can produce 2024年8月7日 Fine sand making machine Processing capacity: 5260t/h Production advantage: less affected by material moisture content The fine sand crusher is a crushing equipment with 4 Types Of Sand Making Machine For Aggregate Mining2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the The Complete Guide to Primary Crushing, Secondary days is in need of finding cost effective and reliable materials for increasing the strength of concrete The scope of this project is to ascertain ability of using the waste PET bottles as a partial replacement agent concrete with 1%, 2% for fine aggregate in and 3% replacement of PET bottle fibers for fineEffect of Plastic Waste as Partial Replacement of Fine Aggregate in

3 Steps For Stone Crushers Crush Stone To Sand

2024年5月7日 1 Crushing The first step in breaking stones into sand is to crush them, which breaks them into small pieces The stone crushers include jaw crushers, cone crushers, and impact crushersDifferent crushers can perform 2023年2月23日 CostEffective: One of the main advantages of sand crushing machines is that they are costeffective These machines are designed to process large amounts of raw material quickly and efficiently, which means that construction companies can save both time and money on their building projectsA Comprehensive Guide to Sand Crushing Machines240T/H Granite Crushing Line In Russia Related Equipments: vibrating feeder, jaw crusher, cone crusher, sand maker and vibrating screen Details Granite Crushing And Screening Line In Norway Main Equipments: PE1200×1500 jaw crusher, cone crusher, vibrating scree, vibrating feeder and conveyorcrushing sand into powder Sebocom Construction2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?

Top Tips on How to Manufacture Highquality M Sand

2024年9月10日 Sand washing equipment types: Wheel and spiral type sand washer Wheel sand washing machine: The capacity is 15–300 t/h The feed particle size is within 10 mm Less fine sand loss Spiral sand washer: The capacity is 5–240 t/h The feed size is within 10 mm It has a cleaner washing effectDo you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needsTypes of Rock Crushers Quarry Crushing Equipment Kemper2024年11月11日 Our glass recycling systems also produce a distinctly different product: A rounded glass particle, 3/8″ in size or finer If material other than glass (plastic, metal caps, or covers) goes through the pulverizer, these materials will keep their larger form and thus be easily separated from the glasssand within the trommel separatorGlass Pulverizer Systems Turn Glass To Sand! Andela Products2023年2月23日 CostEffective: By enabling efficient processing of raw materials, crushing and screening equipment can reduce construction costs significantly This is particularly important for largescale projects, where even small savings can add up to significant cost reductionsCrushing and Screening Equipment: The Backbone of Modern

Home Powdercrush Portable Battery Powered Pill

Lightweight, portable, and built to last, the Powdercrush™ is an ideal product for longterm care, pharmacies, hospitals and correctional facilities Powdercrush™ saves time, eliminates the problem of cross contamination and crushes meds 2016年4月7日 Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations However, theoretical Selecting the right type of crushing equipment2023年5月27日 Grinding process is to produce grade wise powder form from activated bentonite or natural bentonite Raymond mill is a popular bentonite grinding equipment Learn more about bentonite Raymond mill The particle How to Dry, Grind and Granulate Your Bentonite Clay?this is prolly the best/easiest way to do it quick it's just always good to put inside any other clean loose maggie because based on the integrity/strength of the chem, ur gonna pick that baggie up that now has perfect powder to you will either notice right then and there if you lucky orrrr you'll notice after it after a few times of taking the baggie out and wondering when ur have looks [Equipment] Something to crush crystals into powder?

Crushed rock sand – An economical and ecological alternative to

2016年9月1日 The cost of concrete production primarily depends on the cost of its constituent raw materials namely, cement, aggregates (coarse and fine) and water Among the constituent raw materials, the Natural River sand which forms around 35% of the concrete volume plays an important role in deciding the cost of concrete2019年7月8日 Within the past 20 years, however, equipment suppliers guaranteeing their equipment performance have had to “beefup” the design Gypsum just didn’t crush like a soft rock Despite being soft, Gypsum is tough, a factor which is of critical importance when developing equipment specificationsCrushing Grinding of Gypsum 911Metallurgistcrush stone into powder fine crusher with iso quality crush stone into powder fine crusher with iso quality Ore beneficiation equipment, sand making equipment, crushing equipment and powder grinding equipment, which are widely used in Henan Mining Machinery and Equipment Manufacturer How To Crush Find here Sand Crush, Crushed Sand manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Sand Crush, Crushed Sand across IndiaSand Crush Crushed Sand Latest Price, Manufacturers Suppliers

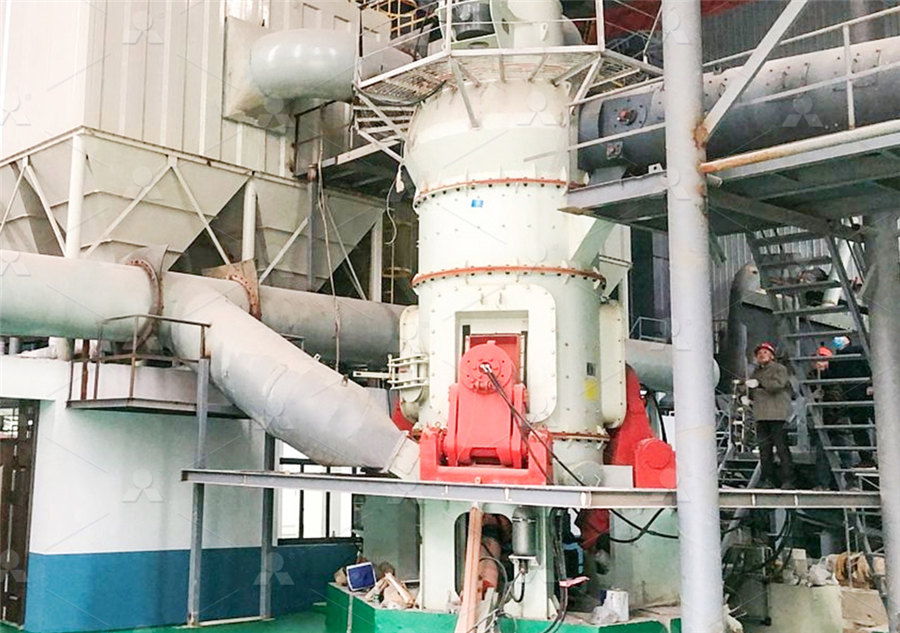

Sand Making Production Line JXSC Machinery

The sand making production line, also called sand making plant, is the full equipment used to produce artificial sand and gravel materialsIt can efficiently crush, shape and screen raw materials into required sizes Its sand making system combines various machines such as vibrating feeders, jaw crushers, cone crushers, impact crushers, sand making machines, Everything else is just fill Gravel, and sand chew up space, so you don't waste all your money on the strengthening glue If you grind up a block of concrete, you will have a bag of very fine (and incidentally, toxic) dust If you add water, it will become If I take a concrete block and grind it down to a fine powder and 2016年1月11日 The figures must be regarded only as a rough guide to the average costs of modern installations ; they are direct costs and include no overhead charges It is assumed that power is charged to the plant at the rate Crusher Operating Costs: How to Optimize and Reduce2019年7月31日 Not only can you easily crush up pills to a fine powder but this 304 stainless steel mortar and pestle functions more than just a medicine and spice herb grinder UNMATCHED PERFORMANCE MAXIMUM CRUSHING Pill Crusher 304 Food Grade Stainless Steel Mortar

Transforming Rocks into Fine Crushed Stone:

Let’s discuss the significance of crushed stone, how to crush stone, and the suitable equipment for the job The Role of Crushed Stone Across Industries Crushed stone is derived from mining suitable rock deposits and processed to 2020年11月6日 Despite the variation in the effect of stone dust on concrete workability due to the different physical characteristics of SD found in the various mining companies around the globe, such as Utilization of Stone Dust as an Effective Alternative for Sand In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the following:Cone A Detailed Overview of Cone Crushers and What You Need to 2021年1月29日 FlackTek™ Speed Mixer grinding using the FormTech Scientific ring grinding system represents an entirely new approach to laboratory scale high energy grindiGrinding Coarse Sand to Fine Powder in a FlackTek™ Speed Mixer

}@~3SRDG`IA1KP_ICWAA.jpg)

Quartz Processing Mastering the Art of Stone to Powder

2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Lightweight, portable, and built to last, the Powdercrush™ is an ideal product for longterm care, pharmacies, hospitals and correctional facilities Powdercrush™ saves time, eliminates the problem of cross contamination and crushes meds to a superfine powder Helps reduce the chance of repetitive strain injuries for nursesPowdercrush Powdercrush2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral 2015年2月24日 The cost associated with highcapacity processing of a hard, finegrained, silicarich magnetite ore is presented in this paper, with the emphasis on comminution circuit options The objective is to evaluate several options involving different grinding technologies with respect to energy consumption, operating cost and capital costEcoefficient and costeffective process design for magnetite iron

.jpg)

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the days is in need of finding cost effective and reliable materials for increasing the strength of concrete The scope of this project is to ascertain ability of using the waste PET bottles as a partial replacement agent concrete with 1%, 2% for fine aggregate in and 3% replacement of PET bottle fibers for fineEffect of Plastic Waste as Partial Replacement of Fine Aggregate in 2024年5月7日 1 Crushing The first step in breaking stones into sand is to crush them, which breaks them into small pieces The stone crushers include jaw crushers, cone crushers, and impact crushersDifferent crushers can perform 3 Steps For Stone Crushers Crush Stone To Sand2023年2月23日 CostEffective: One of the main advantages of sand crushing machines is that they are costeffective These machines are designed to process large amounts of raw material quickly and efficiently, which means that construction companies can save both time and money on their building projectsA Comprehensive Guide to Sand Crushing Machines

crushing sand into powder Sebocom Construction

240T/H Granite Crushing Line In Russia Related Equipments: vibrating feeder, jaw crusher, cone crusher, sand maker and vibrating screen Details Granite Crushing And Screening Line In Norway Main Equipments: PE1200×1500 jaw crusher, cone crusher, vibrating scree, vibrating feeder and conveyor2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?2024年9月10日 Sand washing equipment types: Wheel and spiral type sand washer Wheel sand washing machine: The capacity is 15–300 t/h The feed particle size is within 10 mm Less fine sand loss Spiral sand washer: The capacity is 5–240 t/h The feed size is within 10 mm It has a cleaner washing effectTop Tips on How to Manufacture Highquality M SandDo you need to process sand, gravel, minerals, rock, or other aggregate products and have not yet purchased or leased crushing equipment? There’s no question—you need to work with a capable and professional material handling equipment design and engineering company dedicated to selling, renting, and installing the best new crushers for your needsTypes of Rock Crushers Quarry Crushing Equipment Kemper

Glass Pulverizer Systems Turn Glass To Sand! Andela Products

2024年11月11日 Our glass recycling systems also produce a distinctly different product: A rounded glass particle, 3/8″ in size or finer If material other than glass (plastic, metal caps, or covers) goes through the pulverizer, these materials will keep their larger form and thus be easily separated from the glasssand within the trommel separator2023年2月23日 CostEffective: By enabling efficient processing of raw materials, crushing and screening equipment can reduce construction costs significantly This is particularly important for largescale projects, where even small savings can add up to significant cost reductionsCrushing and Screening Equipment: The Backbone of Modern