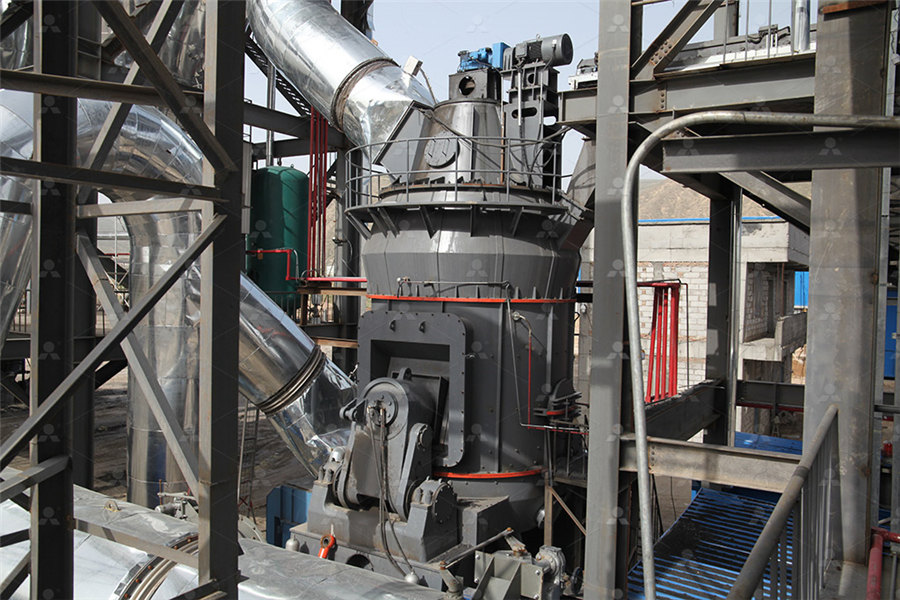

Ttype ore mill general plan

.jpg)

Telfer Project Process Plant Design PDF Mill (Grinding) Mining

This document summarizes the process plant design for the Telfer gold/copper mining project in Western Australia It discusses the extensive metallurgical testwork conducted on the diverse General ore type : The general type of ore will ultimately dictate the plant design and the detail of sampling and testwork required A simple, nearsurface, freemilling gold ore may require only ETALLURGICAL PROCESS D PLANT ESIGN AusIMMThis paper presents guidelines for studies required for the development of mineral processing facilities from initial feasibility studies through to commissioning Mining project schedule and Guidelines for mineral process plant development studies AusIMMMethods of ore transportation used in over 90 underground and openpit mines are listed briefly in Section 32 (Table 1), and more detail is found later in this section and in Section 10, Storage OneMine Design of Plants

.jpg)

Project Development Plan Artemis Gold Inc

The Blackwater Project will comprise the construction, operation, and closure of an open pit gold and silver mine and ore processing facilities commencing with a nominal milling rate of The purpose of the MOP is to summarize mill design, milling and production rates, plans for and identification of stockpiles, details on reagent use and storage and the requirements for load Minto Mine Mill Operations Plan 201801Consider a 1000 t/h processing plant which achieves a 05% improvement in throughput at grind at target size This is an additional 5 t/h for 360*24*09 or 38 880 t over a year at 90% Design for sampling—preliminary exploration AusIMMthyssenkrupp VELIX® Stirred Media Mill is designed for the challenges of future ore processing Challenges like increasing energy costs, lower ore grades and fine grained ores require an Designed for the challenges of future ore processing

.jpg)

Mine/Mill production planning based on a Geometallurgical Model

2016年6月1日 This paper describes the development of a practical, fast and inexpensive technique to quantify minerals from routine chemical assays Ore samples and process The design of an oreprocessing plant requires a high degree of cooperation among the geological, mining and metallurgical engineers The purposes of this section are to provide mill OneMine Mill Design2021年2月8日 Furnaces often had different arrangements If you plan to use a Walthers kit you will have two iron tracks under the cast house and the slag runner will be on the outside wall on one side of the furnace On the high line Modeling a Steel Mill WAS: Highline for delivering 2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution

Mill Operators’ Conference 2018

mineralisation, lithology, alteration and coarseore competencies; and consists of variable densities that can range between 26 t/m3 for the quartzrich mineralisation to 40 t/m3 for magnetiterich mineralisation In combination with variable densities and coarseorecompetencies, the SAG mill feed rates vary significantlyMinto Explorations Ltd – Minto Mine 2018 Mill Development and Operations Plan January 2018 6 Table 21: Ore Stockpiles Material Type Copper Grade Range Soluble Copper Blue Sulfide Ore 050 – 100% Cu 200% Cu 150% Cu >150%Minto Mine Mill Operations Plan 201801MILL OPERATING PLAN VERSION 200601 Prepared by: Yukon Zinc Corporation In Association with: general mill building layout, reagent use, concentrate haulage, power plant The projected production rate for the mine is set at 1440 t/d of diluted ore, based on 1250 t/d of mill feed plus an additional 190 t/d of flotation rock from the DMS Wolverine Project• General ore type: The general type of ore will ultimately dictate the plant design and the detail of sampling and testwork required A simple, nearsurface, freemilling gold ore may require only a small amount of sampling and testwork A complex base metals sulphide deposit willETALLURGICAL PROCESS D PLANT ESIGN AusIMM

Fine grinding: How mill type affects particle shape characteristics

boratory test work indicated a significant difference in product particle shape characteristics for the two mill types, the difference was not evident in the plant data 1 Introduction 11 Background With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which haswith mill tailings likely being one of the volumetrically most important A suite of over 80 mill tailings samples from more than 20 mineral deposit types was assembled to evaluate environmental risks related to mill tailings and to evaluate their byproduct resource potential on the basis of mineral deposit type (tab 1) Samples were obtained Environmental Attributes and Resource Potential of Mill 2022年12月31日 This study used a CCD (central composite design) of RSM to determine the dependence and interaction between several operating conditions that affect the grinding process using a ball mill, such as OPTIMIZATION OF LATERITE ORE GRINDING PROCESS USING BALL MILL 5 天之前 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage grinding equipment Ball Mill Is Indispensable For Lithium Ore Processing

.jpg)

(PDF) Planning an Iron Ore Mine: From Exploration

PDF On Jan 1, 2013, Jim Everett published Planning an Iron Ore Mine: From Exploration Data to Informed Mining Decisions Find, read and cite all the research you need on ResearchGatemodern oredressing plant; they are the governors that control and balance one part with the other These human beings are the most important pieces of machinery in the whole plant1 T hese words, written in 1913 to implore mill designers to factor in people when planning ore dressing plants, have notBreaking Ore, Breaking Bodies: The Wear and Tear of Work at an 2018年4月11日 HPGR and Ball Mill Products of a SnT a Ore Sarbast Ahmad Hamid 1, * ID , Pura Alfonso 1 ID , Hernan Anticoi 1 ID , Eduard Guasch 1 ID , Josep Oliva 1 , Marek Dosbaba 2 , Maite GarciaV alles 3 ID Quantitative Mineralogical Comparison between HPGR and Ball Mill type of mill, operating conditions, and type of ore ground [1] 2 Experimental research The relative consumption of electric energy is the ratio of the useful power consumed by the mill's electric drive to the efficiency of the grinding cycle without taking into Control of ball mill operation depending on ball load and ore

.jpg)

[GUIDE] How to fix mass mill/mass prospect, crafting values of Reddit

How you can use either custom sources in your tooltips or macros to quickly find out which herb or ore is the cheapest to destroy to get those materials This part has two methods with their own pros and cons, but in general you'll be able to find out what the best way to source your materialsEducational games and videos from Curious George, Wild Kratts and other PBS KIDS shows!PBS KIDSMining Equipment Copper Ore Rod Mill of Mineral Processing Plant, Type: Rod Mill: Motor Type: AC Motor: Contact Supplier Chat Still deciding? Get samples of US$ 30000/set Request Sample formulate a preliminary plan according to the specific situation of customers, Mining Equipment Copper Ore Rod Mill of Mineral Processing PlantPDF On Jan 1, 2011, W M Jansen and others published Tracerbased minemill ore tracking via process hold ups at Northparkes mine Find, read and cite all the research you need on ResearchGate(PDF) Tracerbased minemill ore tracking via process

.jpg)

Track Plan and Operations for a Paper Mill the MRH Forum

Hi All, Looking for some feedback on the track plan and operations for this paper mill layout It's a ProtoFreelanced DOMTAR Pulp and Paper Mill making finished computer paper and cardboard The era is early 2000s The paper mill yard connects to a spur (on the layout) that leads to the mainline This spur also leads to several other industries (off the layout) A CN local picksup SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore Grindability• A 61 km Overland Conveyor discharging ore to a 360,000 tonnes Mill Coarse Ore Stockpile • 2 x 36’ x 19’ ABB Svedala Gearless Motor Drive 134MW SAG Mills • 4 x 20’ x 335’ Svedala 7,400 kW Ball Mills • 4 x MP1000 750 kW Pebble Crushers • 4 x clusters of 26” WEIR Cavex CyclonesBATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING tomill (D2M) project to optimize the drill and blast, load and haul, and comminution circuit operations in order to achieve an extra 05 Mt/a from the benchmarked ore production of 20 Mt/a This implies increasing mill throughput from 260 – 270 t/h to 320 t/h assuming 89% mill availability (23% increase in mill throughput)DRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS PUSTYNNOYE

An Overview Of the SmAllScAle teStS AvAilAble tO chArActerize Ore

146 and a median of 148 kWh/t bOnd rOd mill GrindAbility The Bond Rod Mill Grindability Test is performed similarly to the ball mill test The feed sample is stagecrushed to ½” and the test is run under a 100% circulating load As in the ball mill test, the test can also be closed with various sieve sizes, but for AG/SAG2015年8月6日 The third type of mill that I mentioned was an AUTOGENOUS MILL, this type of mill uses a completely different type of grinding media; the rock itselfIn 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise AG Autogenous GrindingAG Autogenous Grinding 911MetallurgistRod Mill The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drumUnderstanding the SAG Mill in Copper Ore Mining Process2019年4月19日 At new ore locations, power system stiffness doesn’t seem to be growing as fast as large mill sizes High starting current (usually of low power factor) drawn through the utility system,ant transformers, and plant distribution networks causes voltage dipsElectric Drives for Large Ore Grinding Mills 911Metallurgist

Mineral Processing Plant Design Construction Example

2016年6月3日 The grinding mill is a 5′ x 5′ lefthand Type “B” steelhead Ball Mill with a righthand “V” to flat drive on the feed end of the mill The ball mill is powered with a 50Hp, 900rpm, 440 volt Westinghouse Synchronous Motor The mill rpm is 253 and is started by a Westinghouse DeIon Linestarter2018年11月18日 The general term “domain” here refers to a volume or physical space with (ore type, ore class, weathering type A mining plan defines the ore sequence prior to coming to the processing (PDF) Simulation of a Mining Value Chain with a Synthetic Ore 2023年11月8日 11 Definition and Function of Ore Types The fate of any rock in a mine is predetermined before the shovel touches it It has already been classified as a particular ore type, a numerical tag that describes what path it will be routed on: waste, mill, leach, stockpile, etcThe ore type serves as a guide to what operations will be performed, how much recovery can be Ore Types: What They Are, How They’re Made, and Their Uses and INTEGRATION OF IRON ORE DEPOSIT EVALUATION AND MINE PLAN FOR SELECTING COST EFFECTIVE and TS Suresh Kumar Natural Resources Division, General Office 3rd Floor, Tata Steel, Jamshedpur , India 1Joda East Iron Mine, Tata INTEGRATION OF IRON ORE DEPOSIT EVALUATION AND MINE PLAN 1259 MATERIAL TYPE BUFFER INTEGRATION OF IRON ORE DEPOSIT EVALUATION AND MINE PLAN

Modeling a Steel Mill WAS: Highline for delivering

2021年2月8日 Furnaces often had different arrangements If you plan to use a Walthers kit you will have two iron tracks under the cast house and the slag runner will be on the outside wall on one side of the furnace On the high line 2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution mineralisation, lithology, alteration and coarseore competencies; and consists of variable densities that can range between 26 t/m3 for the quartzrich mineralisation to 40 t/m3 for magnetiterich mineralisation In combination with variable densities and coarseorecompetencies, the SAG mill feed rates vary significantlyMill Operators’ Conference 2018Minto Explorations Ltd – Minto Mine 2018 Mill Development and Operations Plan January 2018 6 Table 21: Ore Stockpiles Material Type Copper Grade Range Soluble Copper Blue Sulfide Ore 050 – 100% Cu 200% Cu 150% Cu >150%Minto Mine Mill Operations Plan 201801

.jpg)

Wolverine Project

MILL OPERATING PLAN VERSION 200601 Prepared by: Yukon Zinc Corporation In Association with: general mill building layout, reagent use, concentrate haulage, power plant The projected production rate for the mine is set at 1440 t/d of diluted ore, based on 1250 t/d of mill feed plus an additional 190 t/d of flotation rock from the DMS • General ore type: The general type of ore will ultimately dictate the plant design and the detail of sampling and testwork required A simple, nearsurface, freemilling gold ore may require only a small amount of sampling and testwork A complex base metals sulphide deposit willETALLURGICAL PROCESS D PLANT ESIGN AusIMMboratory test work indicated a significant difference in product particle shape characteristics for the two mill types, the difference was not evident in the plant data 1 Introduction 11 Background With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which hasFine grinding: How mill type affects particle shape characteristics with mill tailings likely being one of the volumetrically most important A suite of over 80 mill tailings samples from more than 20 mineral deposit types was assembled to evaluate environmental risks related to mill tailings and to evaluate their byproduct resource potential on the basis of mineral deposit type (tab 1) Samples were obtained Environmental Attributes and Resource Potential of Mill

.jpg)

OPTIMIZATION OF LATERITE ORE GRINDING PROCESS USING BALL MILL

2022年12月31日 This study used a CCD (central composite design) of RSM to determine the dependence and interaction between several operating conditions that affect the grinding process using a ball mill, such as 5 天之前 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage grinding equipment Ball Mill Is Indispensable For Lithium Ore Processing