Cangzhou calcium carbonate limestone crusher smelting waste residue crushing station

Recycling and utilization of calcium carbide slag ScienceDirect

2022年5月1日 CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are Coal is the dominant fuel in China to provide primary energy, and 70% of current status and new oppo2024年1月19日 Substituting Portland cement (PC) clinker with limestone has been demonstrated to effectively reduce CO 2 emissions while enhancing the properties of cement Maximising the benefits of calcium carbonate in sustainable 2023年9月15日 The use of calcium carbide sludge (CCS) as a substitute for limestone is an effective method for reducing CO 2 emissions in the cement industry In this study, a life cycle Life cycle assessment of beneficial use of calcium carbide sludge in

Recycling and utilization of calcium carbide slag 百度学术

Therefore, the recycling of CCS decreases the need for limestone extraction, leading to reduced CO2 emission, energy consumption, and solid waste pollution For example, if CaO is 2022年5月1日 CaC2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are Recycling and utilization of calcium carbide slag ResearchGate2014年12月1日 Environmental impacts of precipitated calcium carbonate manufacturing are estimated Alternative production methods are compared using a partial life cycle assessment Cradletogate life cycle assessment of precipitated calcium 2019年5月23日 Although carbide slag is the competitive calcareous material to produce cement clinker, but a series of calcium waste residue, such as limestone slag, waste lime, and carbide Comprehensive Utilization of Carbide Slag SpringerLink

Life cycle assessment of beneficial use of calcium carbide sludge in

The use of calcium carbide sludge (CCS) as a substitute for limestone is an effective method for reducing CO emissions in the cement industry In this study, a life cycle assessment (LCA) Calcium oxide or calcium carbonate prepared from carbide slag is further used in calcium carbide production On the one hand, it can get rid of the dependence of calcium carbide production Resource utilization of solid waste carbide slag: a brief review of 2024年1月19日 Substituting Portland cement (PC) clinker with limestone has been demonstrated to effectively reduce CO 2 emissions while enhancing the properties of cement (PDF) Maximising the benefits of calcium carbonate in sustainable Calcium Carbonate Crushing Production Line Aggregate Crushing Plant Limestone Crusher Equipment in Mining and Quarry, Find Details and Price about Tracked Mobile Stone Crushing Plant Crawler Type Mobile Stone Crusher Calcium Carbonate Crushing Production Line

.jpg)

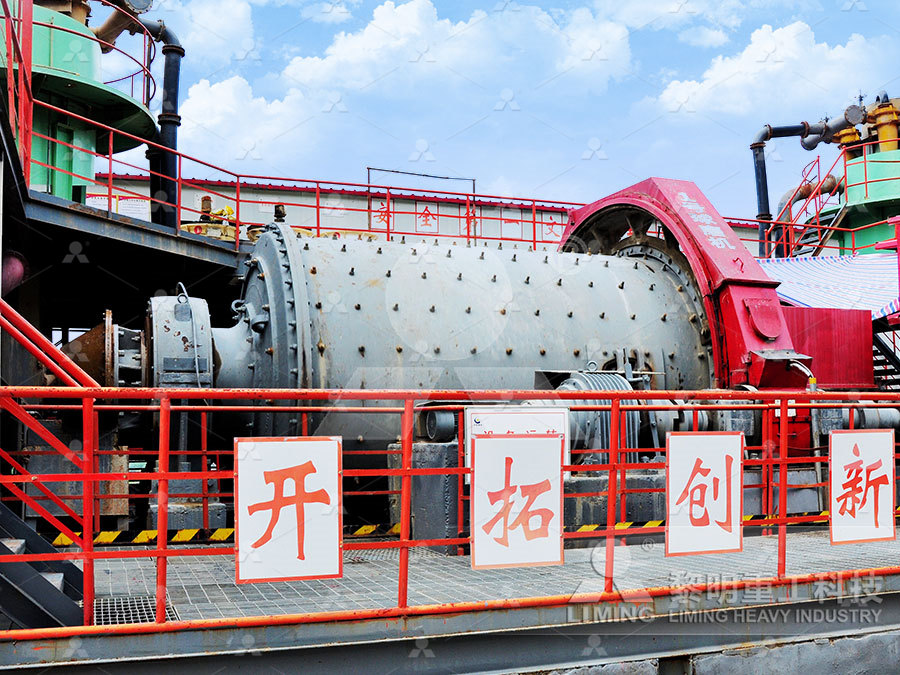

Limestone Crusher for Efficient Limestone Crushing

Limestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material Calcium Carbonate Mill, Calcium Carbonate Crushing ball mill Calcium Carbonate Crusher Calcium Carbonate Limestone Calcium Carbonate Processing Plant, Stone Crusher Price In limestone crushing and grinding process, quite possibly the most frequently utilized crushers and grinding mills are limestone jaw crusher, limestone cone crusher Crushing Of Calcium Carbonate Crusher Mills, Cone Crusher, Complete Calcium carbonate processing plant Generally, calcium carbonate can be divided into heavy calcium and light calcium Heavy calcium: Heavy calcium carbonate, also known as ground calcium carbonate, referred to as heavy calcium, is produced by physical methods using natural calcite, limestone, dolomite, chalk, shells, etc as raw materials4 Steps to Build a Calcium Carbonate Processing Plant Zenith CrusherLimestone fines and lime residue waste (lime sludge) may contain more than 95 wt% calcium carbonate (CaCO3), making them highly desirable for many beneficial uses millions of tons of byproduct fines are produced during the crushing and processing of limestone and dolomite quarried in the United StatesLimestone fines and lime sludge: from byproduct waste to

.jpg)

Crusher; Crushing; and Classification Equipment PPT SlideShare

2020年11月8日 1 Mineral Processing: Crusher and Crushing by Hassan Z Harraz hharraz2006@yahoo Ancient and Modern Local Quality and High quality Intranational and Country/Hand made •DOI: 1013140/RG221398236167The jaw crusher is used for primary crushing, and the cone crusher is used for secondary crushing 2 Jaw Crusher Machine + Impact Crusher Machine: Best for soft rock and stone, such as limestone, dolomite, gypsum, bluestone, coal gangue, calcium carbonate, etc The impact crusher shapes particles well 3A Catalog of All Mobile Crushing Station Fote MachineryDownload scientific diagram Process of construction waste grinding: (a) jaw crusher (crushing); (b) threephase induction motor (grinding); (c) vibratory micro mill (fine grinding); (d) material Process of construction waste grinding: (a) jaw crusher (crushing2023年2月7日 Grinding Mussel Shells Into Calcium Carbonate Offers Highvalue Waste Solution Tuesday, 7 February 2023, Shell crusher Preliminary crusher to reduce shells to 1520 mm particlesGrinding Mussel Shells Into Calcium Carbonate Offers Highvalue Waste

Mobile Limestone Crushing Plant Constmach

Constmach mobile limestone crusher is the best solution with excellent cubical shaped of final products, Composed mainly of calcium carbonate (CaCO3), limestone plays a significant role in both natural and industrial processes CONSTMACH mobile limestone crushing plants have become one of the leading solutions in the industry, Limestone is an important raw material of limestone gravel plants, aggregate plants, has a wide range of applications, our company provides the crusher wear parts can increase the life expectancy of 32 times, exports to the United Limestone Crushing Plant, limestone crusher plant, 2019年11月4日 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performance Limestone Rock Crushing Flow Price JXSC Machine2024年1月19日 Effect of calcium carbonate addition on the compressive strength of different types of cements 12,1921,2426,7890 These cements are shown in the subfigures: a Portland cement, b blended (PDF) Maximising the benefits of calcium carbonate in

Limestone Crushing Equipment and Production Line

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcBulkbuy Direct Manufacturer Fine Impact Hammer Crusher for Calcium Carbonate price comparison, get China Direct Manufacturer Fine Impact Hammer Crusher for Calcium Carbonate price comparison from Crushing Machine, Limestone Crusher manufacturers suppliers on Video Channel of MadeinChinaDirect Manufacturer Fine Impact Hammer Crusher for Calcium CarbonateAbout Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC Mineral2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine

Mining crushing stations Metso

Mining crushing stations are unique, cost efficient and modular solutions that provide significant resource and time savings for your mining operation Mining Crushing Stations combines legacy and expertise to bring unique, costefficient and modular solutions2021年10月23日 Calcium carbonatebased shells represent another large group of agro/biowaste The overview of highenergy milling processing of eggshells, oyster shells, shrimp shells, other shells (eg nacre or scallop shells) and bones employing mechanochemical processes is provided in this chapterShells and Other Calcium CarbonateBased WasteThis page is about calcium carbonate waste from sugar production, The calcium carbonate precipitate, residue and this mud is a waste material Sweet sugar recovered by washing the mud is used sugar is utilised in industry In the limestone crushing plant, calcium carbonate waste from sugar production2023年2月14日 Discover the latest technologies and best practices in the limestone crushing industry to increase efficiency and improve the quality of the final product 320t/h Construction Waste Material Crushing Station; 250t/h Optimized Limestone Crushing Process for Increased

Limestone crushing plant PDF SlideShare

2013年6月20日 1 Limestone mobile crusher is the complete crushing unit, includes feeding, crushing, screening process for example, limestone mobile jaw crusher includes vibrating feeder, vibraging screen, primary jaw crusher, Mobile Crusher Plant移动破碎站 Mobile jaw crusher; Mobile crusher plant; Mobile jaw crusher+cone crushing and screening integrated machine; Mobile impact crushing and screening station; Wheel type cone mobile crushing station; Wheeled Jaw Crusher Mobile Crushing Station; Crawler type crushing and screening machine; Crawler mobile XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher 2024年7月10日 Choosing the right primary crusher for limestone crushing 14:51:44 Baichy Consulting Service Overview Of Limestone And Its Uses Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3), typically in the form of calcite or aragoniteChoosing the right primary crusher for limestone crushing BaichyThe present invention concerns a method for producing calcium carbonate containing the steps of extraction of alkaline industrial waste or byproducts using as a first extraction solvent an aqueous solution of a salt formed from a weak acid and a weak base, whereby a vanadiumenriched first residue is allowed to settle and a calciumrich first filtrate is formed, filtration, whereby the first Method of producing calcium carbonate from waste and by

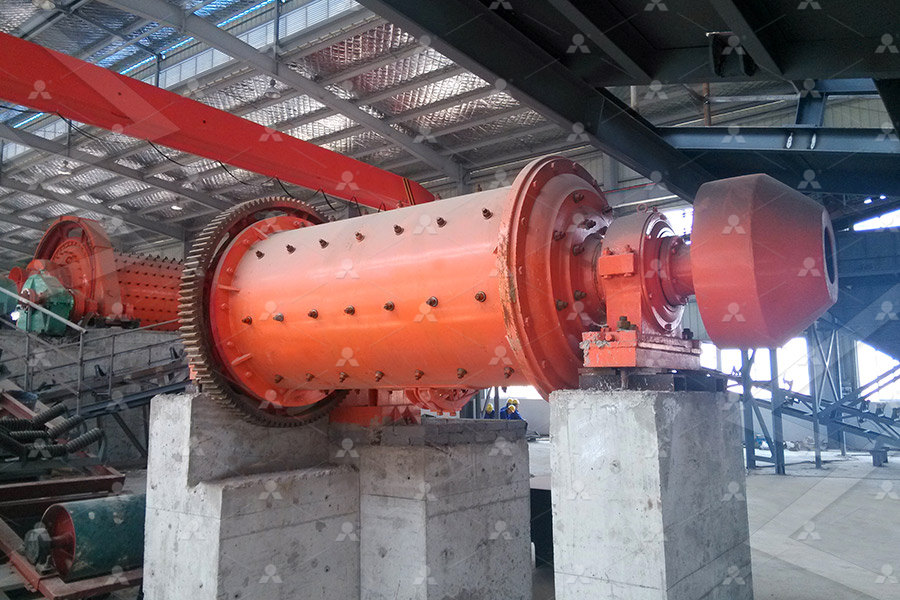

Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them 2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and Equipment2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The 500TPH Limestone Crushing Plant JXSC MachineWaste Construction Materials Mobile Movable Impact Crusher Station, Find Details and Price about Crusher Crushing Machine from Waste Construction Materials Mobile Movable Impact Crusher Station Limestone Outlet Size 1848mm Waste Construction Materials Mobile Movable Impact Crusher Station

.jpg)

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 Lime is produced by decomposing calcium carbonate at temperatures around 9001100 Celsius Calcium carbonate is calcined to produce lime and generate carbon dioxide The ores rich in calcium carbonate mainly include limestone, dolomite, and chalk, etc Furnaces used for calcined calcium carbonate are mainly shaft kilns and rotary kilnsCalcium Carbonate Crushing Production Line Aggregate Crushing Plant Limestone Crusher Equipment in Mining and Quarry, Find Details and Price about Tracked Mobile Stone Crushing Plant Crawler Type Mobile Stone Crusher Calcium Carbonate Crushing Production Line Limestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material Limestone Crusher for Efficient Limestone Crushing Calcium Carbonate Mill, Calcium Carbonate Crushing ball mill Calcium Carbonate Crusher Calcium Carbonate Limestone Calcium Carbonate Processing Plant, Stone Crusher Price In limestone crushing and grinding process, quite possibly the most frequently utilized crushers and grinding mills are limestone jaw crusher, limestone cone crusher Crushing Of Calcium Carbonate Crusher Mills, Cone Crusher,

.jpg)

4 Steps to Build a Calcium Carbonate Processing Plant Zenith Crusher

Complete Calcium carbonate processing plant Generally, calcium carbonate can be divided into heavy calcium and light calcium Heavy calcium: Heavy calcium carbonate, also known as ground calcium carbonate, referred to as heavy calcium, is produced by physical methods using natural calcite, limestone, dolomite, chalk, shells, etc as raw materialsLimestone fines and lime residue waste (lime sludge) may contain more than 95 wt% calcium carbonate (CaCO3), making them highly desirable for many beneficial uses millions of tons of byproduct fines are produced during the crushing and processing of limestone and dolomite quarried in the United StatesLimestone fines and lime sludge: from byproduct waste to 2020年11月8日 1 Mineral Processing: Crusher and Crushing by Hassan Z Harraz hharraz2006@yahoo Ancient and Modern Local Quality and High quality Intranational and Country/Hand made •DOI: 1013140/RG221398236167Crusher; Crushing; and Classification Equipment PPT SlideShareThe jaw crusher is used for primary crushing, and the cone crusher is used for secondary crushing 2 Jaw Crusher Machine + Impact Crusher Machine: Best for soft rock and stone, such as limestone, dolomite, gypsum, bluestone, coal gangue, calcium carbonate, etc The impact crusher shapes particles well 3A Catalog of All Mobile Crushing Station Fote Machinery

.jpg)

Process of construction waste grinding: (a) jaw crusher (crushing

Download scientific diagram Process of construction waste grinding: (a) jaw crusher (crushing); (b) threephase induction motor (grinding); (c) vibratory micro mill (fine grinding); (d) material 2023年2月7日 Grinding Mussel Shells Into Calcium Carbonate Offers Highvalue Waste Solution Tuesday, 7 February 2023, Shell crusher Preliminary crusher to reduce shells to 1520 mm particlesGrinding Mussel Shells Into Calcium Carbonate Offers Highvalue Waste Constmach mobile limestone crusher is the best solution with excellent cubical shaped of final products, Composed mainly of calcium carbonate (CaCO3), limestone plays a significant role in both natural and industrial processes CONSTMACH mobile limestone crushing plants have become one of the leading solutions in the industry, Mobile Limestone Crushing Plant Constmach