HOME→Design of process flow for acidmaking purification section of flue gas of zinc sulfide ore boiling roaster

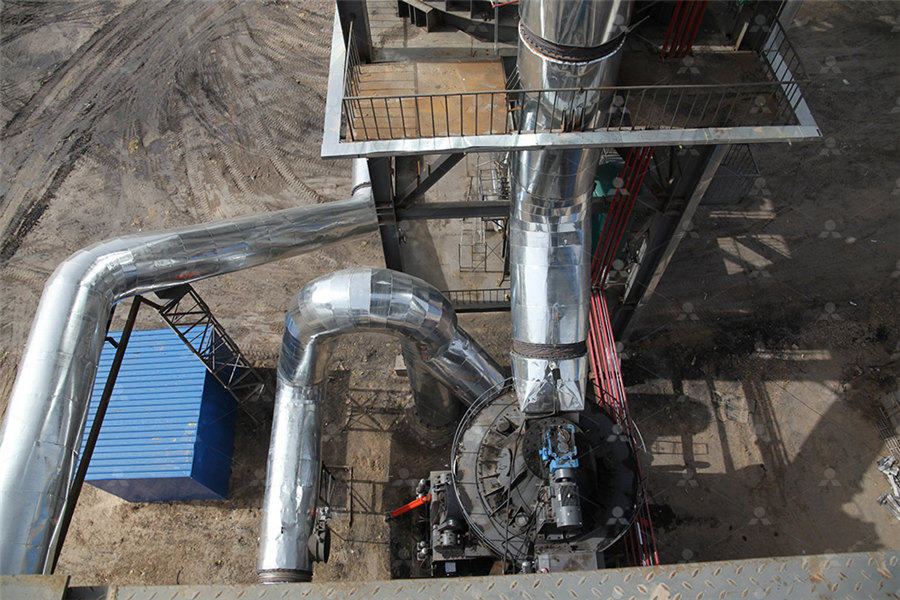

Design of process flow for acidmaking purification section of flue gas of zinc sulfide ore boiling roaster

Summary of research progress on industrial flue gas

2022年1月15日 Through the purification technology of flue gas desulfurization, ultralow emissions of SO 2 flue gas in industrial flue gas can be achieved This article involves dry 2024年6月5日 This review explored and evaluated the various separation processes and technologies for the treatment of industrial flue gases for the control of the associated air Separation processes for the treatment of industrial flue gases Compared to other desulfurization technologies, the activated carbon adsorption method has several unique advantages, including: (1) a compact process flow with high removal efficiency Recent advances in process and materials for dry desulfurization of ;Combined with a smelting flue gas sulphuric acid project, the process flow and main automatic control strategies of the flue gas sulphuric acid production purification section are described to 某冶炼烟气制酸项目净化工段仪表及控制设计Instrument

Flue Gas Desulfurization Systems: Design and Operating

The dry carbon adsorption processes treat flue gases at temperatures lower than 150°C (300°F), which means that they can be located downstream from the power plant air heater and, 2015年7月27日 The WellmanLord process can be used to purify flue gases, with a maximum flow rate of 06 × 10 6 Nm Citation 3 /h, from the combustion of fuels with sulfur content up to Review of Design, Operating, and Financial Considerations in Flue A wet flue gas desulfurizatio (FGD) system for boiler of capacity 300 kg/hr was investigated in this paper It is a set of technologies used to remove sulphur dioxide from exhaust flue gases Analytical Investigation and Design of Flue Gas InpresscoOn an industrial scale process, a comprehensive engineering design and optimization study was conducted for CO2 capture, dehydration, and compression facilities based on flue gases from INDUSTRIAL DESIGN AND OPTIMIZATION OF CO2 CAPTURE,

Summary of Flue Gas Purification and Treatment Technology

2020年5月1日 This paper summarizes the domestic and foreign technologies of waste incineration flue gas purification and treatment, and puts forward suggestions for the 2023年11月1日 In this study, a novel dry capture process utilizing a mixed adsorbent of ZnO and CuS was proposed for the simultaneous removal of Hg 0 and SO 3 in flue gas from zinc PilotScale Experimental Investigation on Dry Capture of Mercury 2021年6月1日 Highpurity NO 2 and SO 2 have significant economic values and are widely used in many fields The large amounts of NO 2 and SO 2 in industrial flue gases are worthy of recovery for environmental protection and economic benefits In this work, a dualcolumn distillation separation process was proposed to further separate and upgrade NO 2 and SO 2 Recovery of highpurity NO2 and SO2 products from ironore Typical process of zinc hydrometallurgy consists of zinc concentrate roasting, calcine leaching, electrowinning, ingot casting and acidmaking Zinc leaching is performed in diluted sulfuric acid system or ammonium system The leaching Zinc Leaching and PurificationZinc Metalcess

Modeling, Design and Optimisation of Industrial Phosphoric Acid

Modeling, Design and Optimisation of Industrial Phosphoric Acid Production Processes aAthanasios I Papadopoulos, aKyriakos Theodosiadis, a,bPanos Seferlis aChemical Process Engineering Research Institute, CERTH, PO Box 60361, 57001 ThermiThessaloniki, Greece bDepartment of Mechanical Engineering, Aristotle University of Thessaloniki, PO Box 2023年3月6日 Optimal production of ammonia (NH3) using natural gas is necessary in order to make it available for wide range of applications including the manufacture of fertilizers, fuel for transportation Process Modeling and Simulation of Ammonia Production from Natural Gas 2019年1月31日 Basic design consi derations of an acid gas removal unit and a dehydration are presented; where th e tar get is the removal of H 2 S, CO 2 and wat er content respectivelyBasic Design of Gas Process Train in Upstream Facilities in 2022年1月15日 In the industrial production of China, the processing of phosphate rock, volcanic eruptions, kerosene combustion and aluminum smelting will lead to flue gas emissions containing a large amount of SO 2SO 2 is a highly irritating gas Because SO 2 is freely soluble in water and enters the respiratory tract, it can generate corrosive sulfurous acid, sulfuric acid, and sulfate Summary of research progress on industrial flue gas desulfurization

(PDF) Numerical simulation study of quench tower in flue gas

2020年9月25日 By establishing a numerical simulation model of the hightemperature flue gas spray evaporation process, the heat transfer and flow processes in the quench tower using 4 different numbers of 2008年8月1日 Interest in recovery of CO 2 from flue gases is being propelled by multiple factors: the merchant CO 2 market, renewed interest in enhanced oil recovery (EOR), and the desire to reduce greenhouse gas emissions This paper reviews the latest processes for CO 2 recovery from flue gases and selects the absorption method with a desirable solvent as a suitable Design of CO2 absorption plant for recovery of CO2 from flue 2015年12月5日 For this purpose chemical absorption with amine solvents is widely used for acid gas removal in gas processing industries The conventional configuration of this process includes two columns: the absorber where amine solvents absorb acid gases and the regenerator where external heat is supplied to drive the desorption reaction and regenerate the amine solvent for Automated process design of acid gas removal units in natural gas 2019年5月1日 Formic acid (FA) is an important chemical with numerous industrial applications It is used mainly as a preservative and antibacterial agent in livestock feed, and to treat textiles and leather (Hietala et al, 2016)As FA is the simplest carboxylic acid, it is also used for the production of several other chemical products (Andrushkevich et al, 2014)Design and optimization of KemiraLeonard process for formic acid

.jpg)

Numerical simulation of wet deacidification process of sludge

2020年11月1日 Deacidification is an indispensable process when cleaning the sludge incineration flue gas To ensure the flue gas meets the emission standard, guarantee the longterm stable operation of the 2021年6月1日 Highpurity NO 2 and SO 2 have significant economic values and are widely used in many fields The large amounts of NO 2 and SO 2 in industrial flue gases are worthy of recovery for environmental protection and economic benefits In this work, a dualcolumn distillation separation process was proposed to further separate and upgrade NO 2 and SO 2 Recovery of highpurity NO2 and SO2 products from ironore 2022年3月4日 Acetone purification is one of the most critical stages of its production process, because a large amount of energy is required Due to this high energy consumption, the process turns out to be not very sustainable and not friendly to the environment In this sense, the development of intensified alternatives that minimize energy consumption in this process is of Sustainable Process Design for Acetone Purification Produced 2024年11月15日 The purification of 5HMF presents a significant challenge for efficient and costeffective production of highpurity 5HMF Notably, the downstream process accounts for approximately 60–70% of the overall cost associated with 5HMF production [2]This complexity arises from various factors, including impurities (such as reaction byproducts and residual Efficient continuousflow separation and purification processes

.jpg)

(PDF) PURIFICATION PHASES OF ZINC SULPHATE SOLUTION

2019年3月1日 In the present study, the production process of zinc sulfate from the zinc oxide ore was experimentally investigated The effect of main operating condition such as weight ratio of sulfuric acid 2017年7月1日 To effectively solve the problem of reutilizing semidry sintering flue gas desulfurized ash (SSFGDA) from steel plants, a new technology is proposed in this paper in which ash is added to a Utilization of SemiDry Sintering Flue Gas Desulfurized Ash for SO 26 P a g e Phosphoric Acid Production 52 Block Flow Diagram (BFD) 1 6 12 2 Reactor 1 3 Filter 4 Reactor 2 7 Separator 1 5 9 Evaporator 13 8 10 Separator 2 11 27 P a g e Phosphoric Acid Production 53 Process Flow Diagram 28 P a g e Phosphoric Acid Production 54 Stream Table 29 P a g e Phosphoric Acid Production 55 Mass Balance on CPE 604Plant Design and Economic AnalysisMini Project Report Sulphuric acid (H2SO4) is of immense importance to the chemical industry and humanity The use of Aspen Plus modeling, simulation, and optimization via the contact process has enabled the Complete Process Flow Diagram of the Sulphuric Acid Production Process

Retrofit of the acid gas sweetening process for the refinery based

2023年3月1日 SulfinolM process, LOCAT process and shell process for natural gas sweetening are also simulated and economically evaluated with the use of Aspen process economic analyzer in order to remove H2S The efficient replenishment and regeneration of HCl and O 2 in flue gas highlighted the utility of chlorinefunctionalized MOFs for oxidizing Hg 0 in flue gas streams (Fig 6 (D)) Currently, various preparation methods of porous materials have been researched and developed to efficiently remove trace amounts of mercury Hg 0 from coalfired flue gasAdvances in porous materials for efficient separation and purification Log Op Man Res 2 superphosphate of lime), steel, pickling of metals, petrochemical, dyestuff, pigments, detergents and explosives (NPCS, 2012; Varnai et al, 2021)Optimized Production of High Purity Sulphuric Acid via Contact Processmethod in flue gas is special, which will be introduced separately in section 223 Wet flue gas purification technology was widely used in some developed countries in the early stage Based on the uniformity of flue gas flow, Qu Jiangyuan [16] proposed a structural optimization schemeIRU'RPHVWLF:DVWH,QFLQHUDWLRQ IOPscience

.jpg)

(PDF) Process for Preparation of Terephthalic Acid ResearchGate

2015年4月30日 Biphasic reactor for conversion of fructose 44 to 5hydroxymethylfurfural with vapor phase reduction of 5hydroxymethylfurfural to 2,5dimethylfuranHydrogen sulfide (H 2 S) existing in natural gas extracted from Qatar's North Field is converted to elemental sulfur using the conventional Claus process Managing byproduct sulfur from natural gas processing is a key aspect of economic development and environmental protection in many countries with oil and gas facilitiesDesign of a Plant to Manufacture Sulfuric Acid from Sulfur2024年6月5日 Globally, gaseous air pollutants have led to altercation of the planet, and this is evident in climate change and global warming These pollutants amongst others include CH 4, SO 2, CO 2, surface O 3, and NO 2Due to the increase in combustion operation and other industrial processes, these gases have been continually released into the atmosphereSeparation processes for the treatment of industrial flue gases Process description Fig 1 shows the process flow diagram of twostage pre combustion CO 2 capture process redesigned to apply to 100 MW class IGCC power plant [25]System diagram of acid gas removal process for precombustion

.jpg)

A novel technical route based on wet flue gas desulfurization process

2020年5月5日 In the process of flue gas purification for coalfired boiler, wet flue gas desulfurization (WFGD) is one of the most important sections [1], [2]In a WFGD system, the injection of a large amount of sorbent solution can remove SO 2 effectively while causing the gas temperature to decrease and the flue gas to be saturated with water Generally, the 2023年5月29日 Sulphuric acid (H2SO4) is of immense importance to the chemical industry and humanity The use of Aspen Plus modeling, simulation, and optimization via the contact process has enabled the Optimized Production of High Purity Sulphuric Acid via Contact Process2024年4月1日 A significant amount of flue gas pollutants (SO 2, NO x, Hg 0, and VOCs) are produced with the growth of human industrial activities including thermal power generation and iron and steel metallurgyActivated coke is a lowcost, highefficiency adsorbent for the removal of pollutants It is the foundational component of dry flue gas purification technology and is easily A review on activated coke for removing flue gas pollutants (SO2, 2021年6月1日 Highpurity NO 2 and SO 2 have significant economic values and are widely used in many fields The large amounts of NO 2 and SO 2 in industrial flue gases are worthy of recovery for environmental protection and economic benefits In this work, a dualcolumn distillation separation process was proposed to further separate and upgrade NO 2 and SO 2 Recovery of highpurity NO2 and SO2 products from ironore

Zinc Leaching and PurificationZinc Metalcess

Typical process of zinc hydrometallurgy consists of zinc concentrate roasting, calcine leaching, electrowinning, ingot casting and acidmaking Zinc leaching is performed in diluted sulfuric acid system or ammonium system The leaching Modeling, Design and Optimisation of Industrial Phosphoric Acid Production Processes aAthanasios I Papadopoulos, aKyriakos Theodosiadis, a,bPanos Seferlis aChemical Process Engineering Research Institute, CERTH, PO Box 60361, 57001 ThermiThessaloniki, Greece bDepartment of Mechanical Engineering, Aristotle University of Thessaloniki, PO Box Modeling, Design and Optimisation of Industrial Phosphoric Acid 2023年3月6日 Optimal production of ammonia (NH3) using natural gas is necessary in order to make it available for wide range of applications including the manufacture of fertilizers, fuel for transportation Process Modeling and Simulation of Ammonia Production from Natural Gas 2019年1月31日 Basic design consi derations of an acid gas removal unit and a dehydration are presented; where th e tar get is the removal of H 2 S, CO 2 and wat er content respectivelyBasic Design of Gas Process Train in Upstream Facilities in

.jpg)

Summary of research progress on industrial flue gas desulfurization

2022年1月15日 In the industrial production of China, the processing of phosphate rock, volcanic eruptions, kerosene combustion and aluminum smelting will lead to flue gas emissions containing a large amount of SO 2SO 2 is a highly irritating gas Because SO 2 is freely soluble in water and enters the respiratory tract, it can generate corrosive sulfurous acid, sulfuric acid, and sulfate 2020年9月25日 By establishing a numerical simulation model of the hightemperature flue gas spray evaporation process, the heat transfer and flow processes in the quench tower using 4 different numbers of (PDF) Numerical simulation study of quench tower in flue gas 2008年8月1日 Interest in recovery of CO 2 from flue gases is being propelled by multiple factors: the merchant CO 2 market, renewed interest in enhanced oil recovery (EOR), and the desire to reduce greenhouse gas emissions This paper reviews the latest processes for CO 2 recovery from flue gases and selects the absorption method with a desirable solvent as a suitable Design of CO2 absorption plant for recovery of CO2 from flue 2015年12月5日 For this purpose chemical absorption with amine solvents is widely used for acid gas removal in gas processing industries The conventional configuration of this process includes two columns: the absorber where amine solvents absorb acid gases and the regenerator where external heat is supplied to drive the desorption reaction and regenerate the amine solvent for Automated process design of acid gas removal units in natural gas